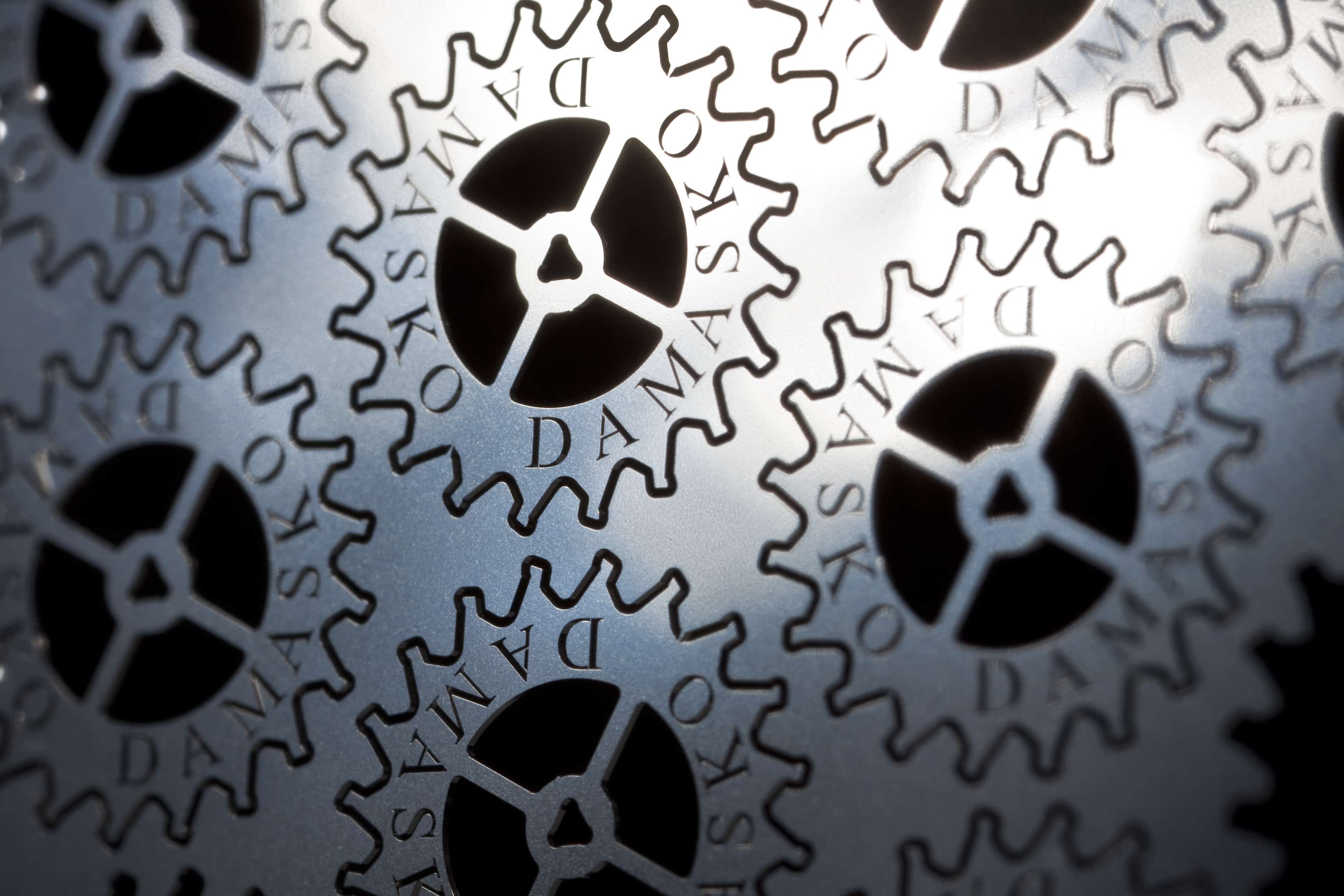

When founder Konrad Damasko first began making watches in the early ‘90s, he did not set out to produce an in-house movement. His initial focus was to over-engineer all the things around the movement, inspired, in part, by the gradual decay of a watch long ago gifted to him for his confirmation. Konrad wanted watches bearing his name to withstand the test of time, and that desire gave birth to hardened cases and crowns, a patented lubrication system, anti-magnetic shielding, and other case technologies that Damasko has come to be known for today.

“It was about identifying the weak points in the watch, and figuring out how they can be improved,” explains Christopher Damasko, Konrad’s son and Damasko’s Technical Director.

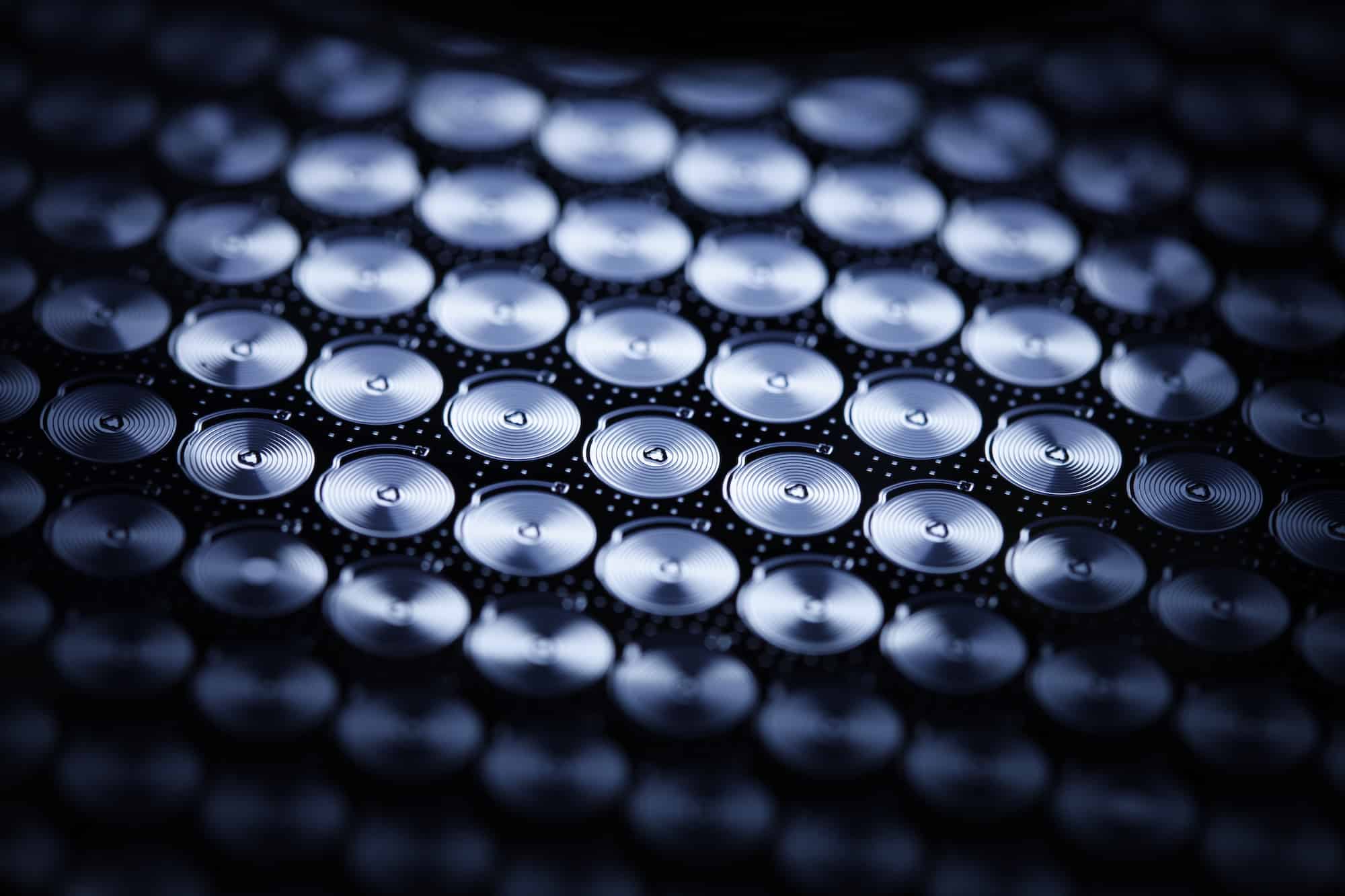

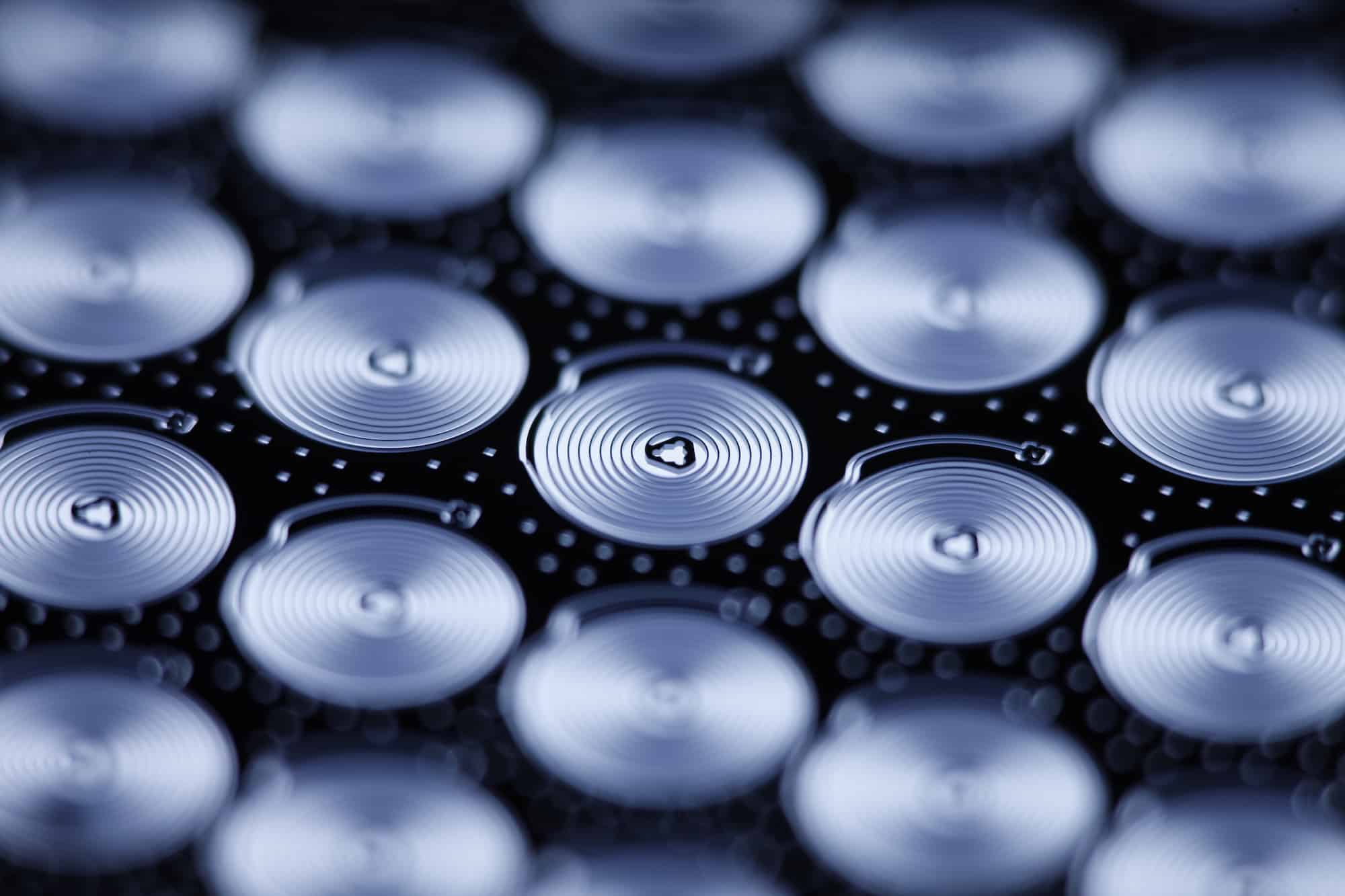

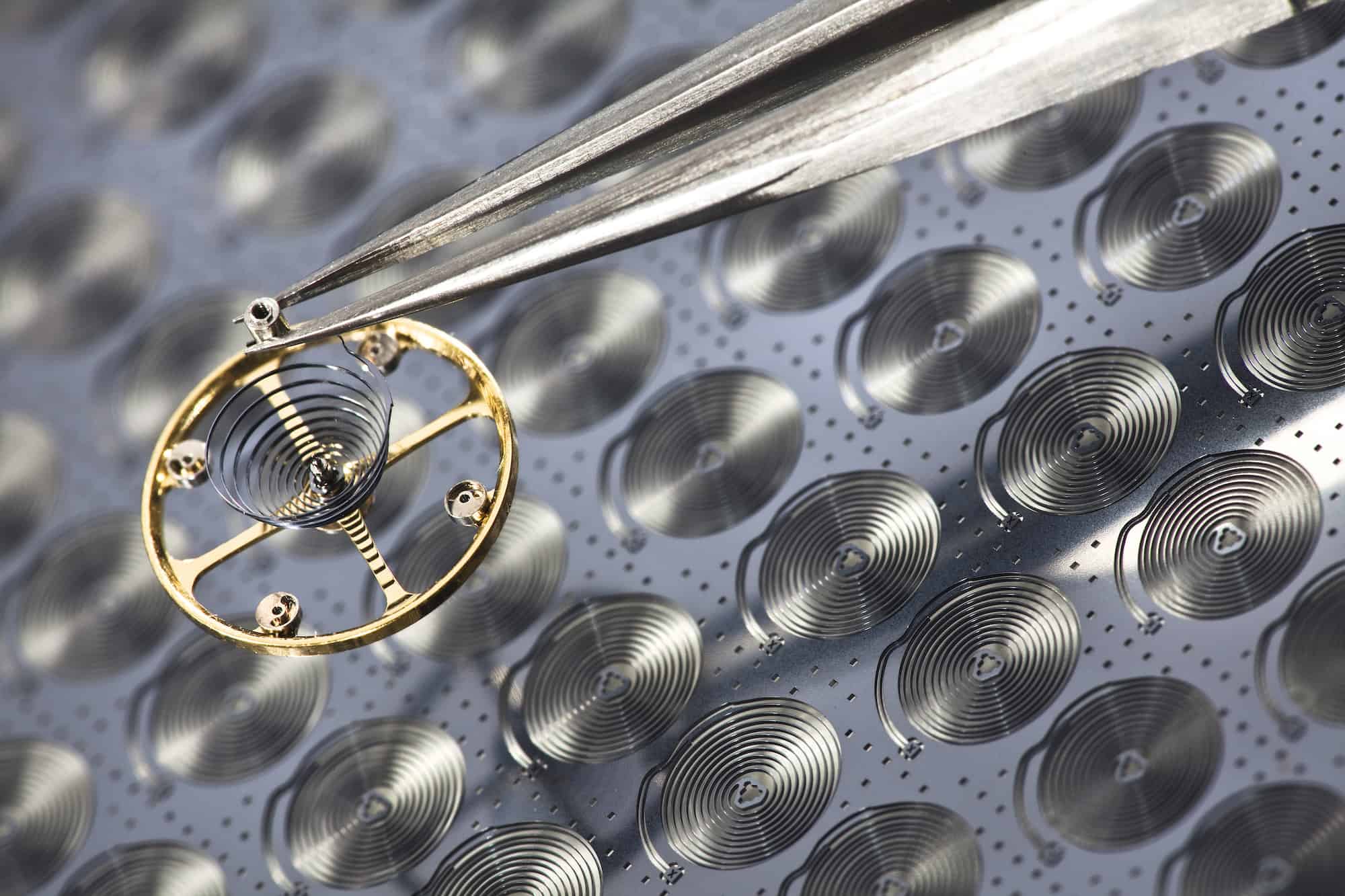

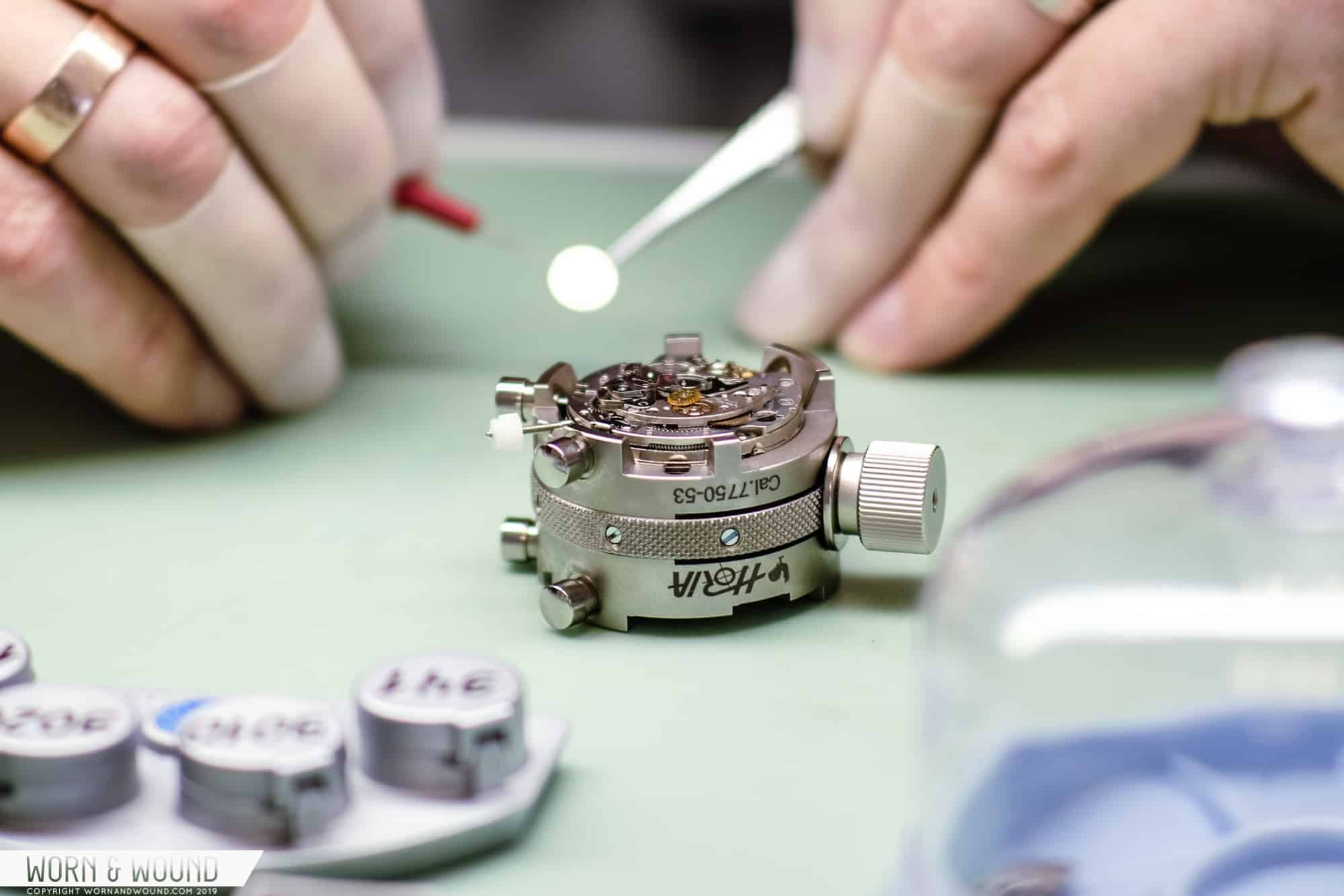

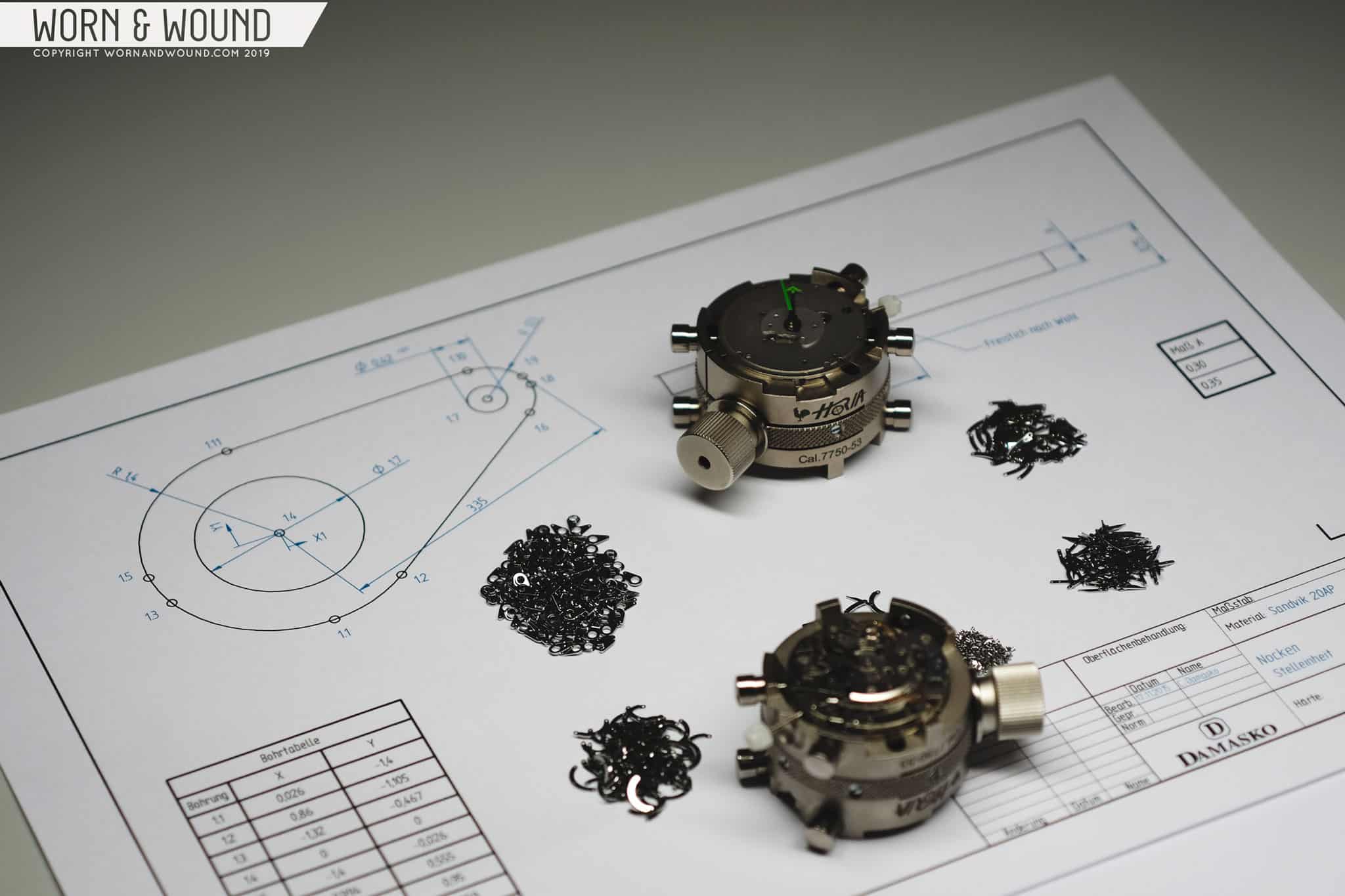

It wasn’t until 2008 that the team turned their attention to the movement. Initially, Damasko put their energy in producing a handful of specific components — among them the oscillating and winding systems — to optimize performance of pre-existing calibers. But then came Swatch Group’s movement crunch, which set the industry scrambling. Damasko was not immune, and Konrad was faced with a difficult choice.

“We asked ourselves, ‘What should we do? Should we just let the whole project die?’” Konrad recalls.

Featured Videos

Featured Videos