Oris has announced their newest in-house movement today in the caliber 400. The movement joins a growing stable of in-house offerings from the Swiss brand, however the caliber 400 stands apart for a few reasons, and is positioned to be the brand’s most accessible ever. Referred to as a “new standard”, the caliber 400 offers a novel take on some basic movement architecture in the name of efficiency, and something probably not discussed enough when it comes to new mechanical movements: longevity. On that front, Oris is standing behind their claims with an impressive 10 year warranty.

Introducing The Oris Caliber 400

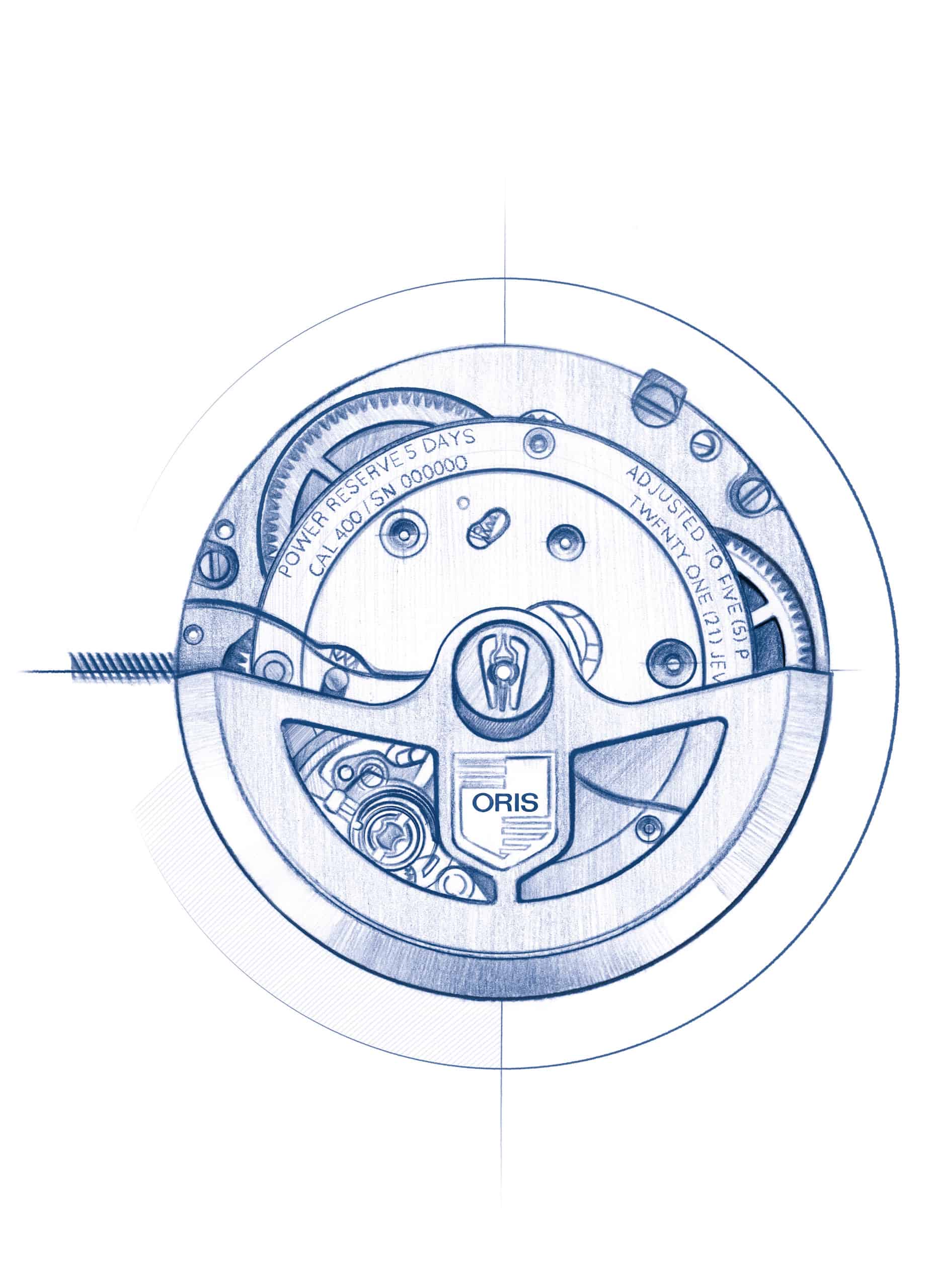

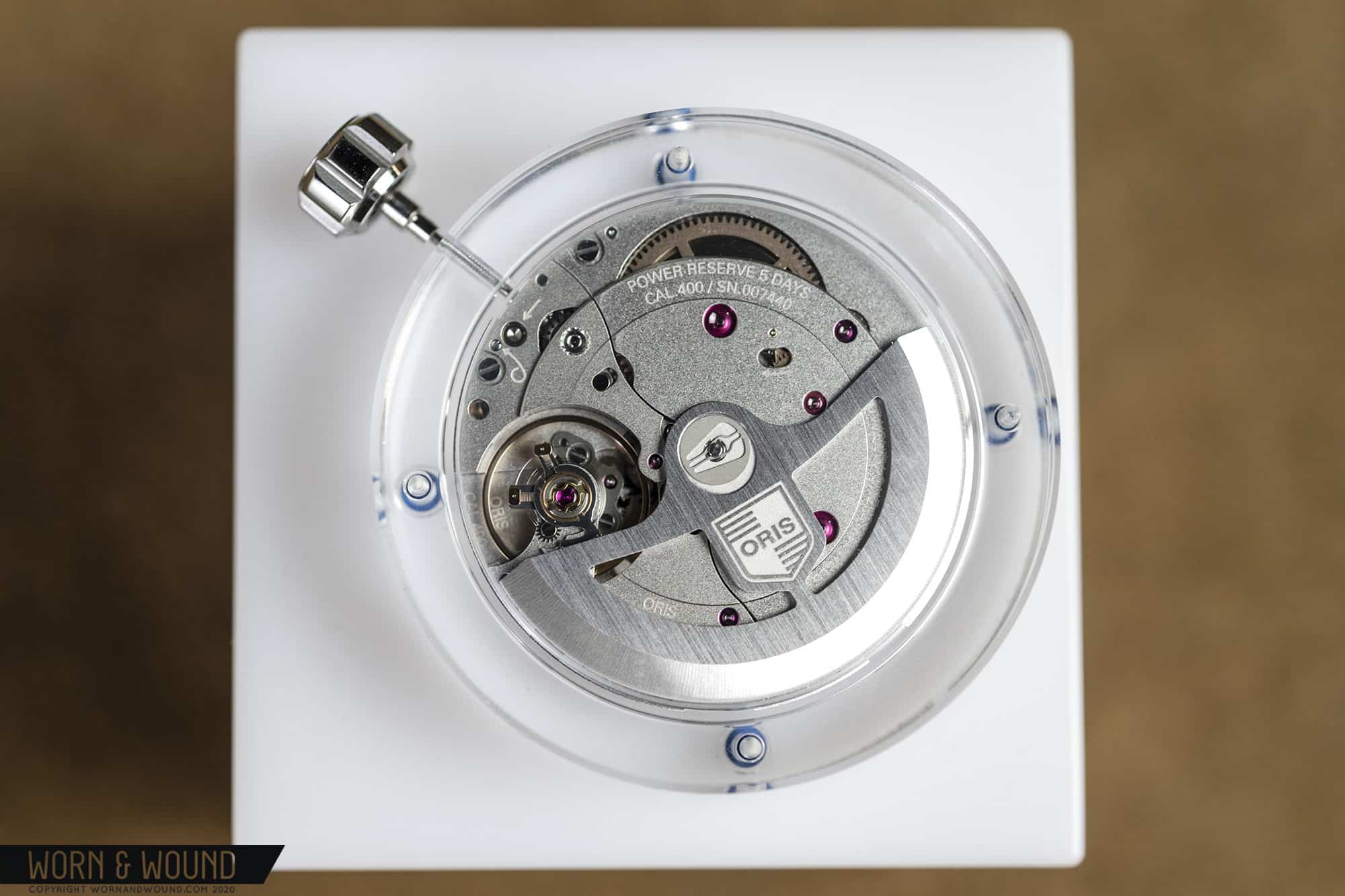

The biggest departure from other in-house movements we’ve seen from Oris in recent years is the move to an automatic winding system from their traditional hand-wound calibers. The lengthy power reserves of these movements, a very healthy 10 days, was something of a necessity, and it’s a trait retained by the caliber 400, which uses twin mainsprings to store 5 days of reserve. Attaining that number without brute force (e.g. bigger springs & barrels) required reducing torque in the mainspring to help conserve power, as well as reducing pressure on moving parts. A new wheel design is also being used that delivers power more efficiently, reducing parasitic drivetrain loss so to speak. The net result is 5 days of reserve delivering 85% of the mainspring’s energy to the escapement, vs the 70% typically seen in automatic movements.

The automatic winding system hasn’t been taken for granted, either. Beat Fischli, Oris’s Chief Operating Officer whose team was responsible for the caliber 400 describes the system they designed thusly: ‘Typically, the rotating mass, or rotor, sits on a ball bearing and winds in both directions. Instead, we devised a much more reliable system based on the slide bearing concept that only winds in one direction. It’s much less complex and reduces wear and tear.’

The escapement that Beat and his team engineered for the caliber 400 uses silicon and other non-ferrous materials where possible to minimize the adverse effects of magnetism on the movement. In total, north of 30 parts are made of non-ferrous materials or non-magnetic alloys, creating an impressively anti-magnetic movement in total all in the name of delivering efficiency and reliability over the long haul to reduce service intervals and keep the movement within spec over the course of its 10 year warranty period.

From a visual standpoint, the caliber 400 forgoes pearlage and striping in favor of a more sober, industrial feel that Oris CEO Rolf Studer tells me was an intentional move on their part. It’s a clean design that feels every bit as modern as the movement is, without letting vanity get in the way. It embraces what it is and bears no pretension of fragility in the process.

Just what watches the caliber 400 will land in remains to be seen, but don’t expect a bespoke concept like the Pro Pilot X for this one. Oris plans on keeping the caliber 400 far more mainstream and accessible. Keep an eye out for more news on that front in the coming weeks.

Featured Videos

Featured Videos