The face of American watchmaking is not a large company. It is small groups of men and women building watches in machine shops, garages and basements across the United States. The face looks something like Matthew and Andy Cook, the two-man operation behind A.M. Cook Wristwatch.

The story of A.M. Cook Wristwatch is similar to many modern American watchmaking companies. It’s a story of struggle, achievement and, finally, of success. The Cook brothers have been making their World War I trench-style watches–cleverly dubbed the 1am–for about six months now. By mid-December, they had shipped out their 19th unit. While it may not sound like a huge milestone to many, it’s a significant achievement for two brothers who had been developing their watch for more than four years before shipping out their first one.

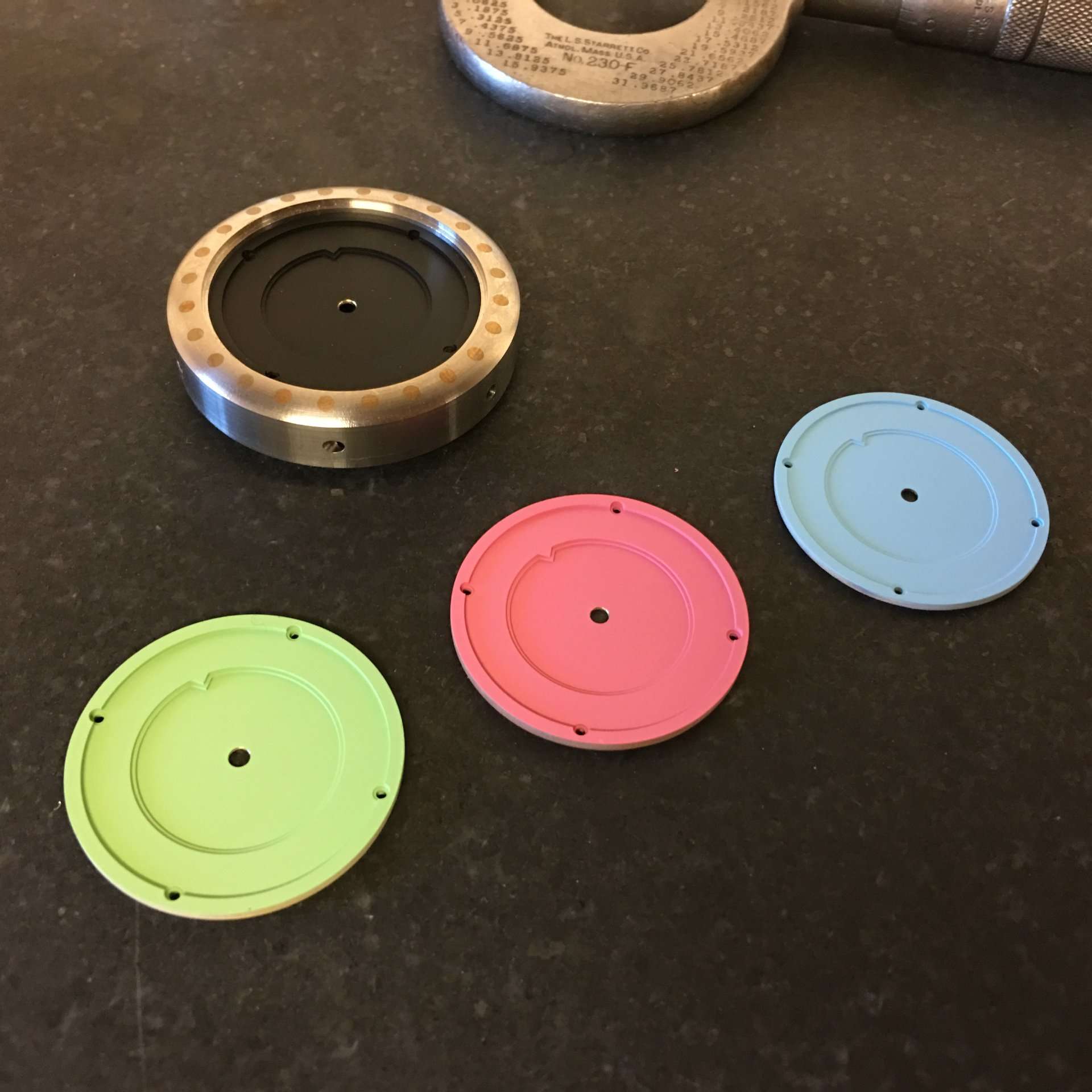

Watches had been a long-time interest of the Cook brothers. But the idea of starting their own company didn’t start until Matt became a trained tool and die maker and Andy became a WOSTEP-trained watchmaker. Matt says he was looking at a picture of a Bell & Ross that his brother had sent him. He looked at the case and realized he could probably make something similar. From that idea sprung four years of research, design and prototyping for their own watch.

Featured Videos

Featured Videos