Cameron Weiss became a watchmaker because he was not impressed by what his peers were doing.

Friends who had graduated ahead of him at University of Southern California business school had accepted job offers that Weiss could not imagine himself doing with his precious time here on earth.

So, he decided to pursue his passion, building watches, something he had become interested in as early as 5, when he took apart his dad’s Seiko after it fogged up during a session in a hot tub.

So, he decided to pursue his passion, building watches, something he had become interested in as early as 5, when he took apart his dad’s Seiko after it fogged up during a session in a hot tub.

“I took it apart but couldn’t do anything with it,” said Weiss in a phone interview with worn&wound. “So it ended being trash. But that was the beginning for me.”

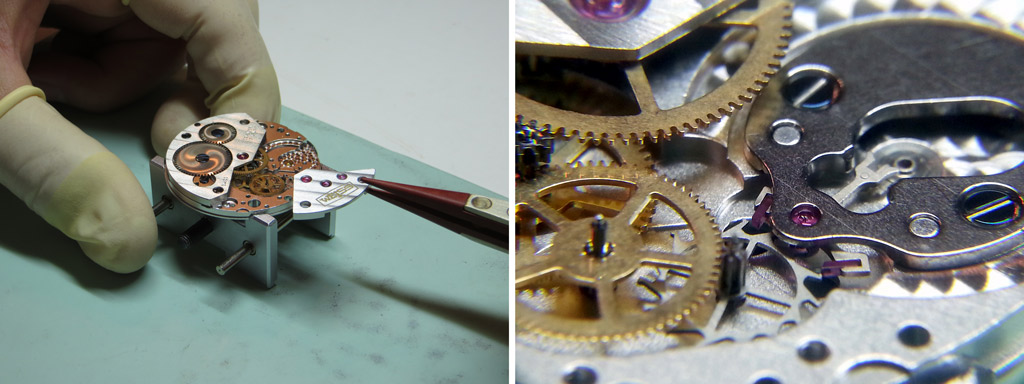

Today, Weiss runs Weiss Watch Company, and builds and assembles his line of mechanical watches all in the United States. He offers a true made-in-America field watch with a manually wound Caliber 6497 that has over 60 Swiss parts that are hand-assembled in Los Angeles. Limited to 500 pieces, somehow the field watch retails for $795.

Weiss, 27, is on a mission to restore the prestige of American watchmaking that was once associated with companies like Elgin and Waltham.

“Well, the goal from the beginning was to create something I would be excited to wear,” said Weiss. “I wanted to do something different and have as many parts made here in the U.S. and assembled here in the U.S.”

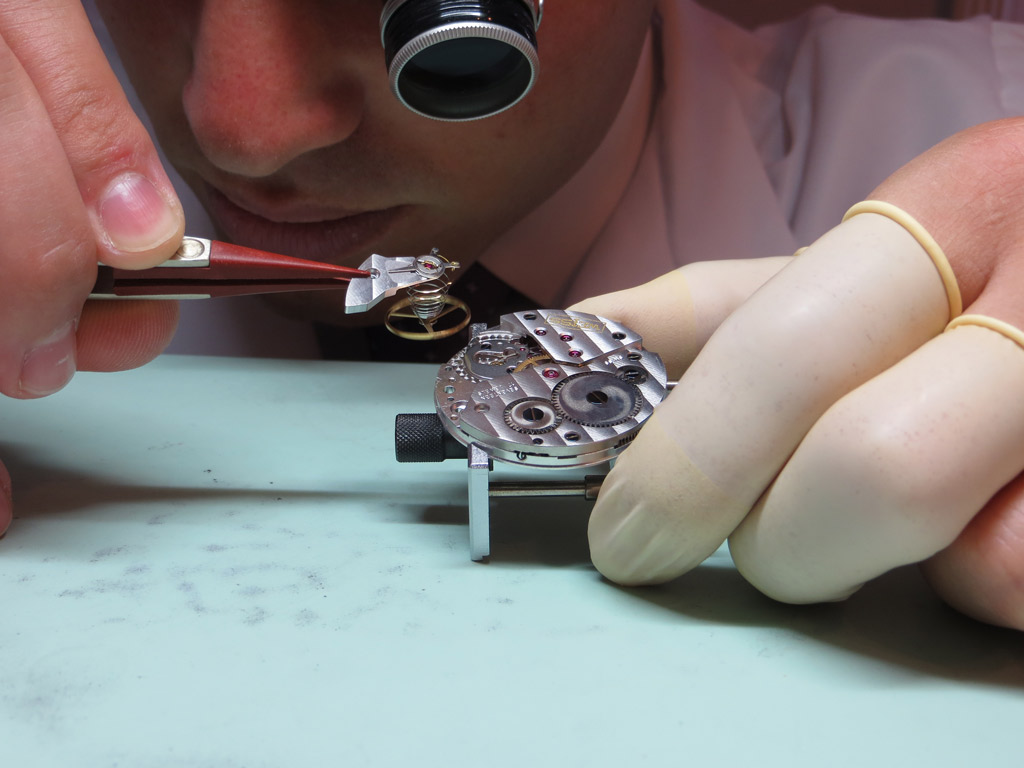

Much of what led Weiss to starting his own company with this mission came from “secrets” he learned training with master Swiss watchmakers through Nicholas G. Hayek School of Watchmaking, where he earned his Watchmakers of Switzerland Training and Education Program (WOSTEP) certification. He worked in service departments for Audemars Piguet and Vacheron Constantin.

“Since I was young watches were always on my gift list,” said Weiss. “I always got watches, Swatches and things like that. Lower end watches. But still an impressive collection for a kid. I also had a big collection of Freestyle watches.”

Weiss first became entranced with automatic watches when he was asked by his parents to choose a watch for his older brother as a college graduation gift.

”They knew I loved watches and how much I knew about them,” said Weiss. “So, I found a pretty cool automatic watch with a 2824. I bought it online through one of the forums, I got a really good deal. The biggest thing I took away from it all was when I went to meet the guy and buy the watch he actually told me about watchmakers and that there are people in Switzerland who assemble these and work on these. I never really thought about a watchmaker I always saw the end product and never really thought about the people that put them together or put them together.”

That sparked Weiss to scour the Internet to learn more about watchmaking and started going into jewelry stores and asking to meet any watchmakers he could to pick their brains.

“I talked to a German guy who was a friend of my parents,” recalled Weiss. “When he found out I was looking into getting into some sort of watchmaking career he said you ought to look into a program called WOSTEP.”

Weiss ended up completing his business administration degree at USC, but his heart was set on learning how to create and fix the tiny mechanisms that made up his lifelong obsession.

“I shifted gears and started focusing on engineering and those kind of things. I bought my own CAD program and dabbling in it while I was finishing school,” he said.

Weiss’s patient personality and talent for fixing things allowed him to quickly succeed in watchmaking school.

“It’s a very serious experience,” he said. “It’s something you have to learn form someone who has been a watchmaker for a long time and has experienced a lot because each watch is going to be different. Even if you have two Rolexes side by side, when you go into each one nothing is going to be the same. So you really need to take everything and focus on very small parts and each individual piece. It takes a long time to grasp that and learn to just be able focus on perfection at a very small level.”

With his mind set on starting his own business, Weiss was inspired by vintage pocket watches.

“I have a few pocket watches and you can pull them out of a safety deposit box and wind it up and it starts ticking,” said Weiss. “They were designed with the tolerances a lot looser so the owner could take it apart, oil the pivots, and this made it something that last. They were meant to be used.”

So far, Weiss said, the customer feedback has been overwhelmingly positive.

“I’ve worked in service centers, so usually I’d be dealing with people who had problems with their watches,” he said. “So far, it’s been a relief that people who have purchases watches from me have been very happy.”

for more on Weiss Watch Co’s watches, check this article

by Li Wang

Photos courtesy of Weiss Watch Co

Featured Videos

Featured Videos