When you stop and think about it, most watches are pretty much the same. Sure, they look different, wildly so, but in the end, they are variations on a theme. Cases change shape, dials change color and markers and hands differ, but they all use 1+ hands to tell the time through a set of agreed upon on intervals displayed in one way or another (well, non-digital at least). These days, what sets a brand apart from the pack can be a great aesthetic, sheer attitude or technological innovation. In regards to the latter, in the high-end you find exceptional artistry and novelty in movements, while in the more accessible price spectrum you find creativity in use of and development of case materials.

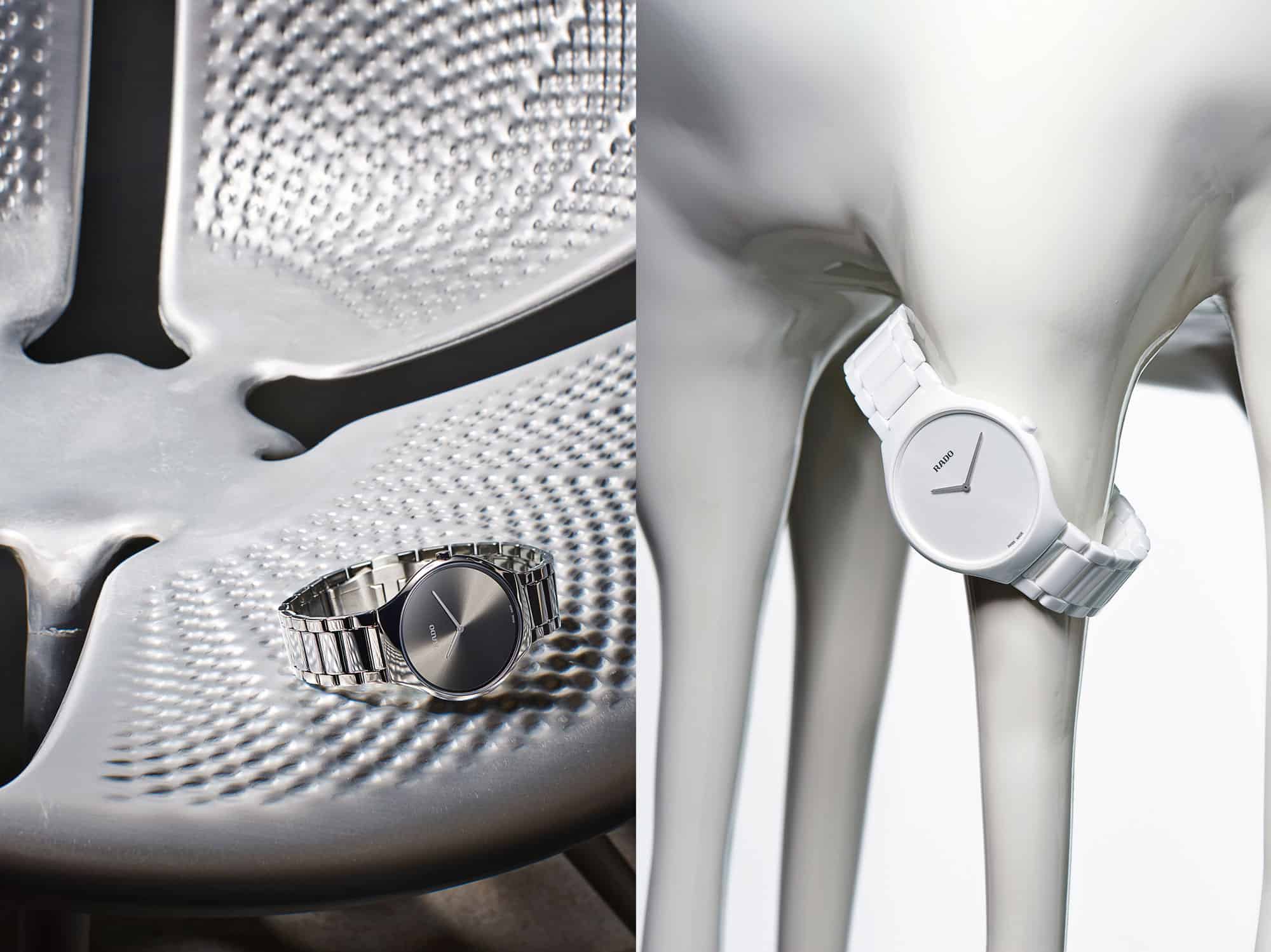

Rado, a Swatch Group brand, has made a name for themselves with their pursuit for ever lighter and more durable materials to create their clean, minimal and modern watches. At the forefront of their catalog is high-tech ceramic. A fascinating material, it’s five times harder than steel, 18 times harder than 18k gold, and far lighter than both. It’s hypoallergenic and temperature neutral, making it very comfortable as well as durable.

Featured Videos

Featured Videos