“Tough Tech” is Worn & Wound’s series that takes a deep dive into the technologies that protect our watches, covering their use throughout watchmaking history, functional benefits, and the watches they’re used in. Check out the first installment on antimagnetic watches right here.

One of the reasons watches are so interesting to me on a personal level is the astonishment I sometimes feel when I consider the fact that these little mechanical tools even work at all. Think about: in a case of stainless steel, or some other metal, you have a finely tuned network of springs and gears that not only work in tandem with each other, but can keep track of the time, a more elusive resource I cannot think of, to mere seconds per day. And it’s all done while you wear it on your body. Consider for a moment the things that your body goes through during the day. It’s in constant motion, subject to sudden changes in direction, and must regularly adapt to forces far beyond its control. And yet your watch ticks on without complaint.

In this installment of our ongoing Tough Tech series, we’ll take a look at the reason your watch can withstand the bumps and jostles of everyday life. Shock resistance has been built into watches for decades – it’s one of the primary reasons wristwatches were ever able to take off in the first place. The ways that watch movements have been protected over the years has changed dramatically in many respects, but the fundamental principles behind shock resistance remain.

Watches are inherently delicate. The balance wheel in particular, which is constantly in motion at a fairly high rate of speed compared to the other moving components of a watch movement, is at an ever present risk of being knocked off plane by the slightest interruption. Timekeeping and the watch’s ability to function at all can be enormously impacted.

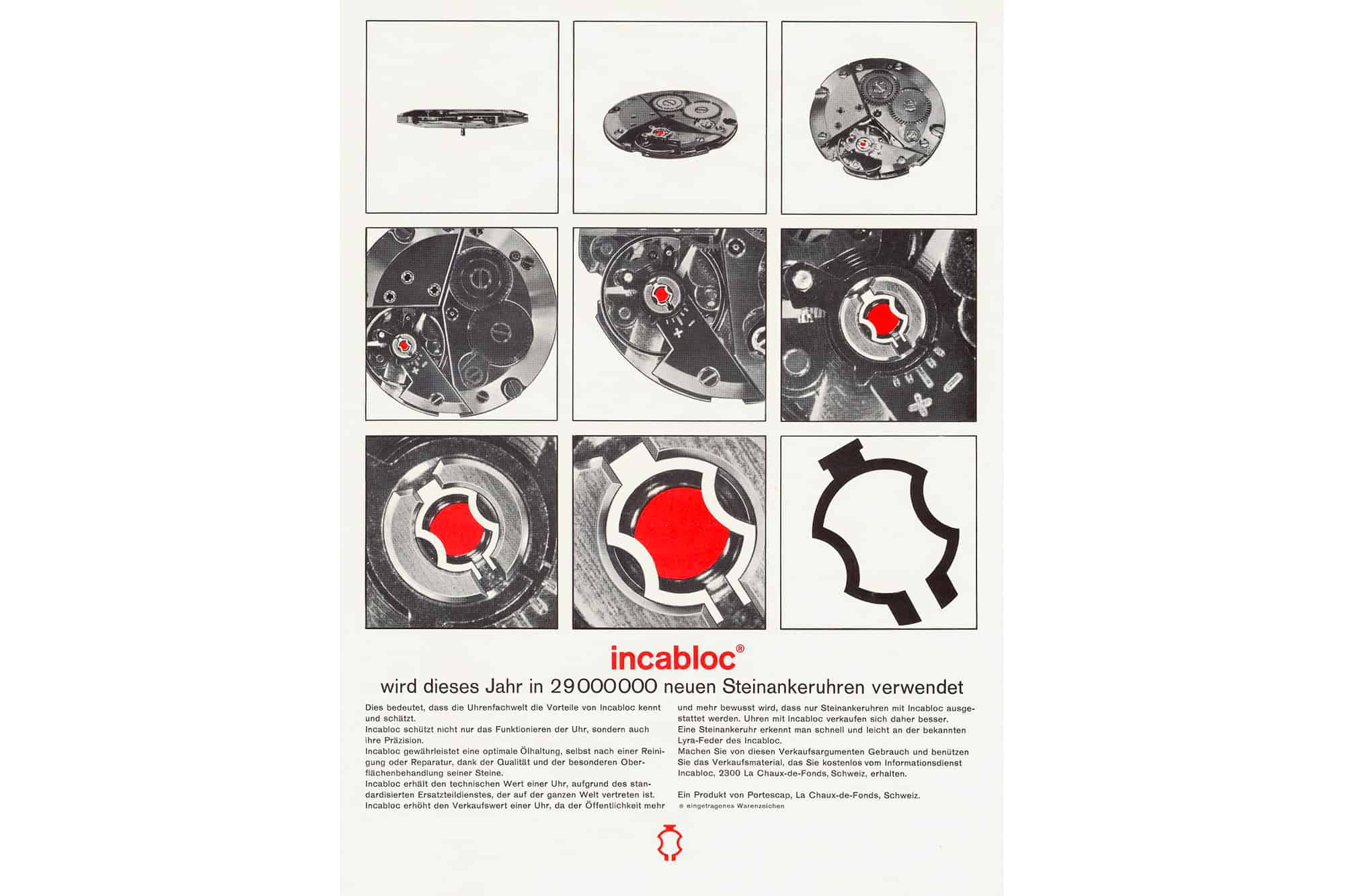

The most primitive and the earliest widespread method of protecting the balance from shock is the Incabloc system. If you’ve even dabbled a little bit in vintage watches, you’ve almost certainly seen the Incabloc signature on many a watch dial.

Featured Videos

Featured Videos