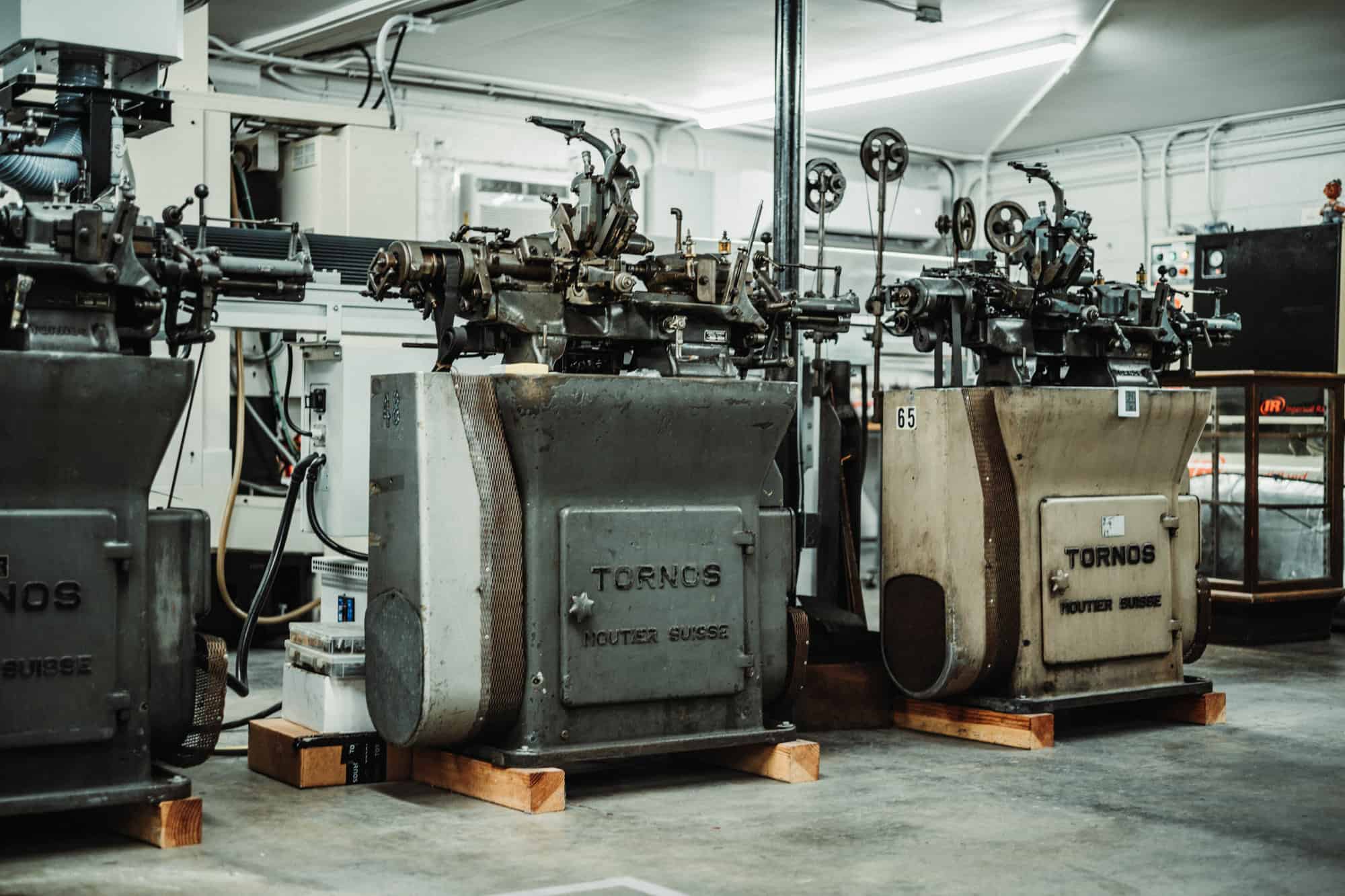

A few weeks ago, Cameron Weiss invited me to his Nashville Workshop to check out some of his latest watches and see the work that is involved in producing a Weiss watch. I took the opportunity to snap a few photos and Cameron was nice enough to have a short interview with me while I was there.

Hey Cameron! Thanks so much for having me in your new shop, it’s been a real eye opener to see all the work that goes into producing a single Weiss Watch Co piece. This shop has a really cool vibe. How old is this building?

I don’t have an exact age of the building, but I think it was built sometime around 1950. Since 1970 it has been home to a family owned vinyl record label print shop and I’m thrilled to be able to preserve the building and some of the Nashville music history from all those years.

I love that we are also a family owned business in an old school industry. Music and vinyl have a fine balance of artistic elements, such as the technology of sound recording and playback sound. This is similar to how watchmaking is a balance between watchmaking as an art-form, the science and technology of timekeeping, and modern manufacturing.

Featured Videos

Featured Videos