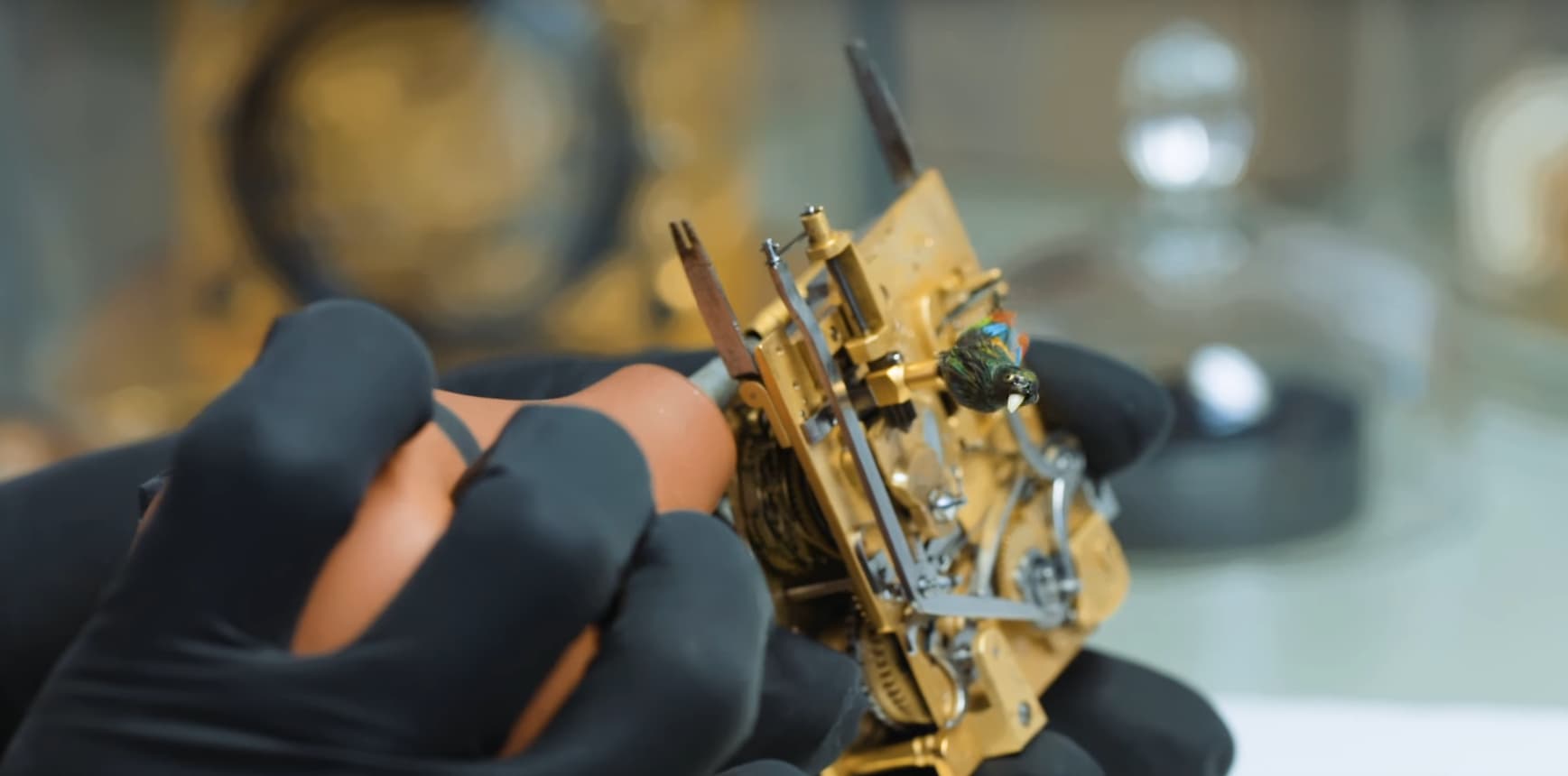

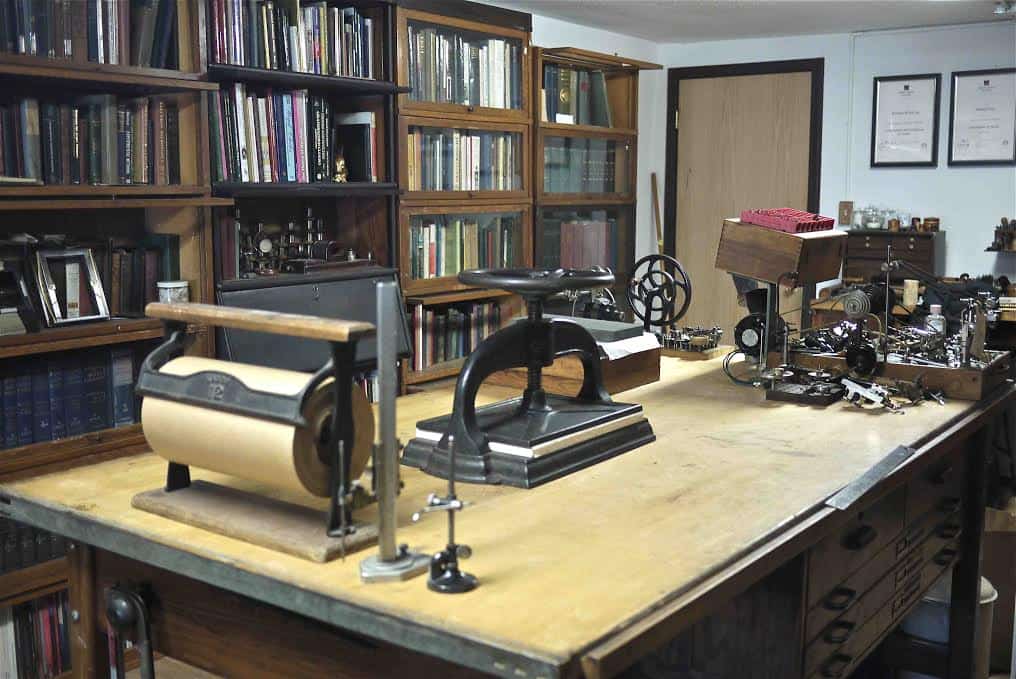

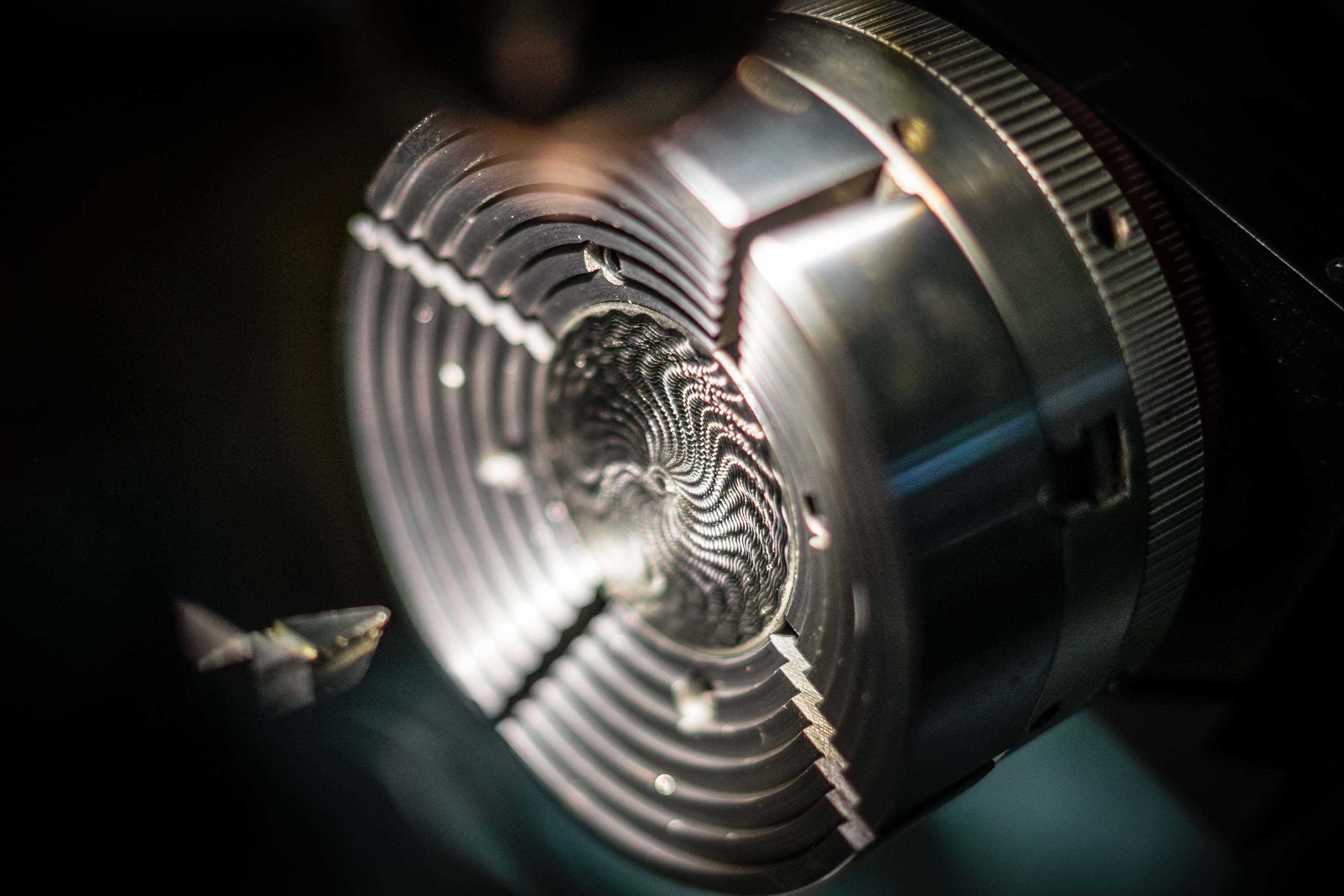

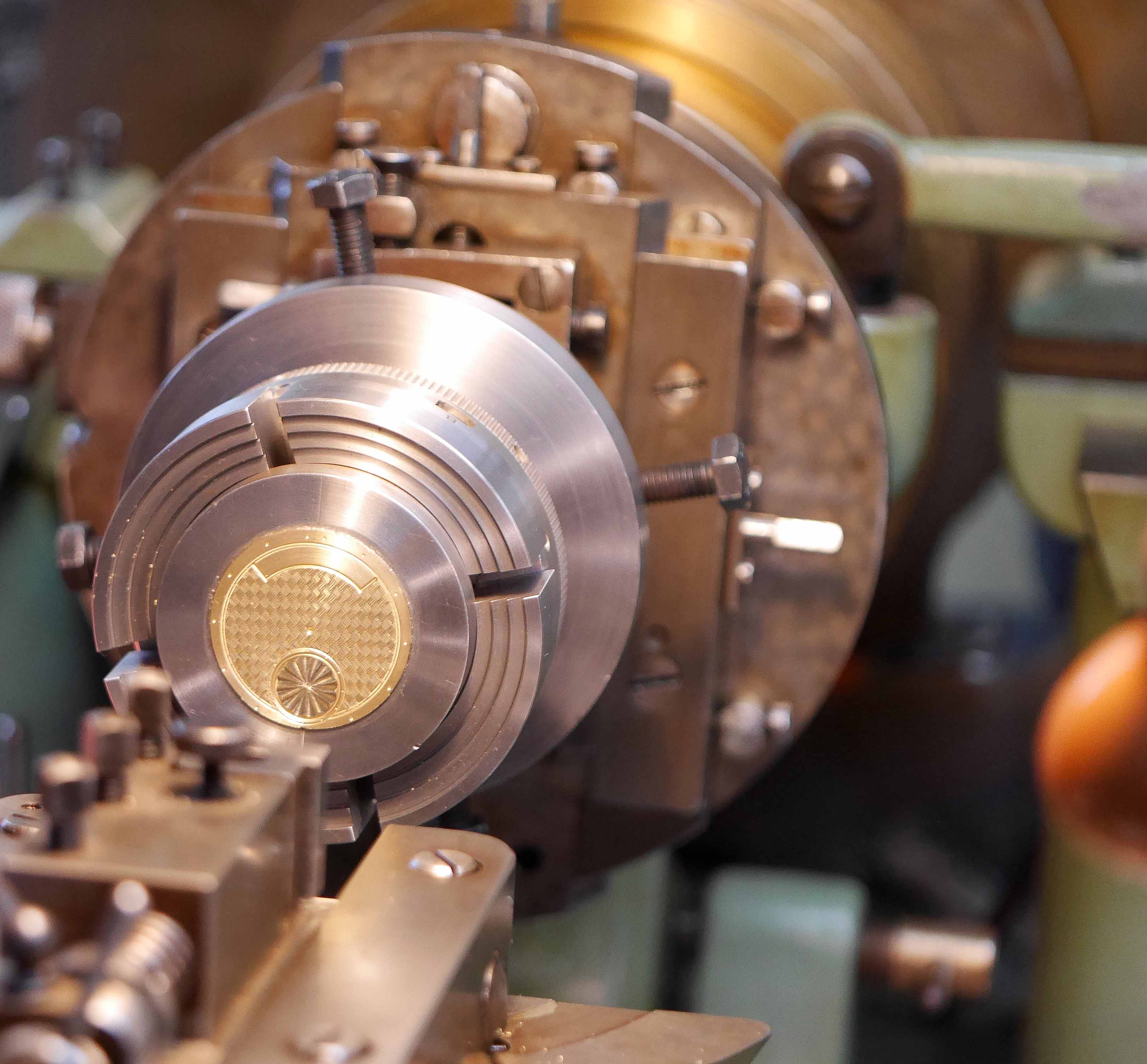

When an item comes into Brittany Cox’s Seattle-based shop, you can be sure that it is old and it is beautiful. Cox is an antiquarian horologist. She works on watches, clocks, music boxes and other pieces of mechanical magnificence every day, seven days a week. It is an all-consuming passion.

But before she had countless hours of training, received numerous watch and clockmaking certifications and repaired and restored some of the most incredible horological masterpieces, she was a young girl with a fascination in how things worked.

Cox explained her interest in mechanical objects began when she started collecting music boxes and watches as a kid. To Cox, there was something enchanting about discovering a mechanical object that could play music or tell time. It was comforting to see something tangible work like that.

“Having something small that works and does something so special held my attention for many years,” Cox said.

Featured Videos

Featured Videos