You know what it’s like. You’re hanging out with one of your pals who just happens to fly a U-2 spy plane for a living. The sort of chap who spends his working day looking down on the world from 70,000 ft. Probably the sort of fellow who’s pretty bored with the “high flier” jokes already. He mentions that he’d quite like a custom-made watch that he can take up in the office. So you offer to make him one.

This is exactly the scenario that engineer and watchmaker Paolo Fanton found himself in last year. As a pilot himself, Paulo knows some of the headaches associated with wearing a watch and flying at high altitudes.

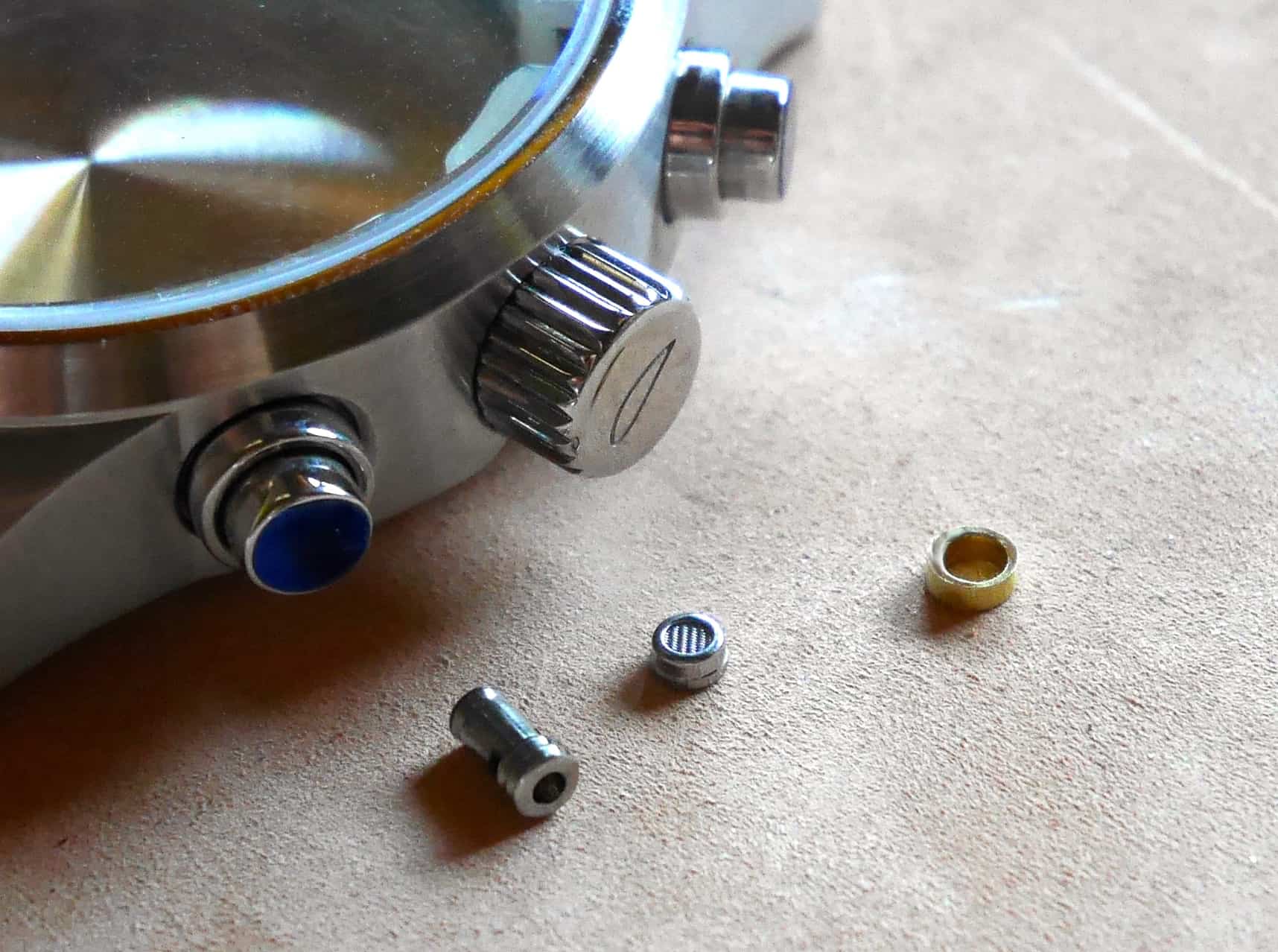

As early aviators discovered, the rarefied atmosphere around the Armstrong Line (circa 60,000 ft) is not a friendly place for either pilots or their watches. As pilots found themselves moving from (relatively) unsophisticated, low-level piston-engined planes to high-speed, jet-propelled, high-altitude aircrafts, these new high speeds and altitudes necessitated the introduction of pressurized cockpits and suits. As far as watches were concerned, with sudden changes in altitude pilots found that the crystals on their watches would pop—they’d be lifted off by the expansion of the gasses inside the watch case. Aircrafts, of course, have cockpit clocks, but pilots are notorious for wanting both belt and braces, so their backup wristwatches needed to cope. The simple solution was to have a lip on the bezel that restricted the crystal’s movement if air pressure dropped, or to fit the crystal from inside the case.

Aircrafts, of course, have cockpit clocks, but pilots are notorious for wanting both belt and braces, so their backup wristwatches needed to cope. The simple solution was to have a lip on the bezel that restricted the crystal’s movement if air pressure dropped, or to fit the crystal from inside the case.

Featured Videos

Featured Videos