Architect Robert Isaac sat down at his desk to change the bracelet on one of his Seiko SKX007 divers. He grabbed for, what he called, his “crappy” spring bar tool. He hated it. It didn’t sit well in his hand and the tips didn’t work well. But what could he do?

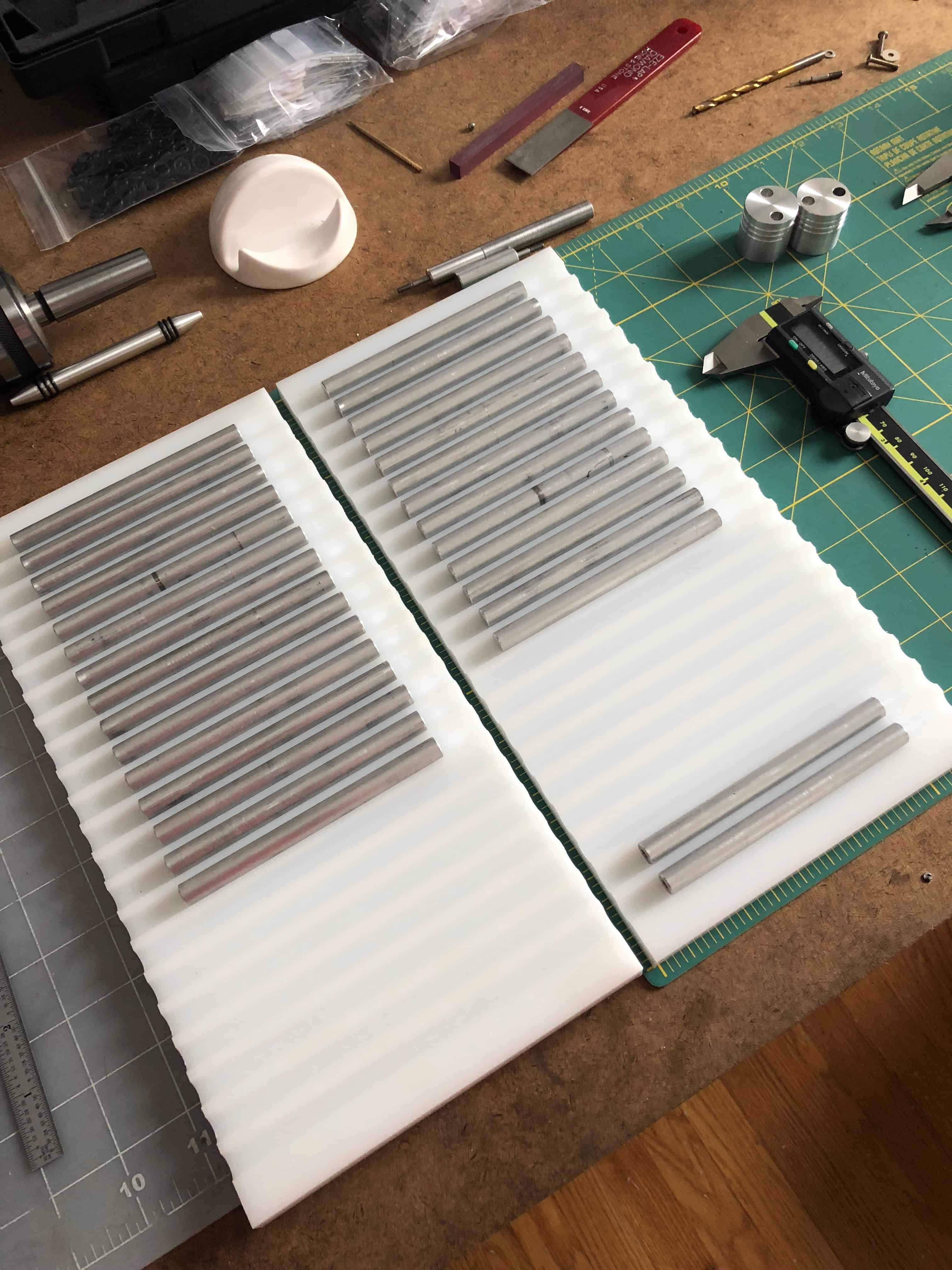

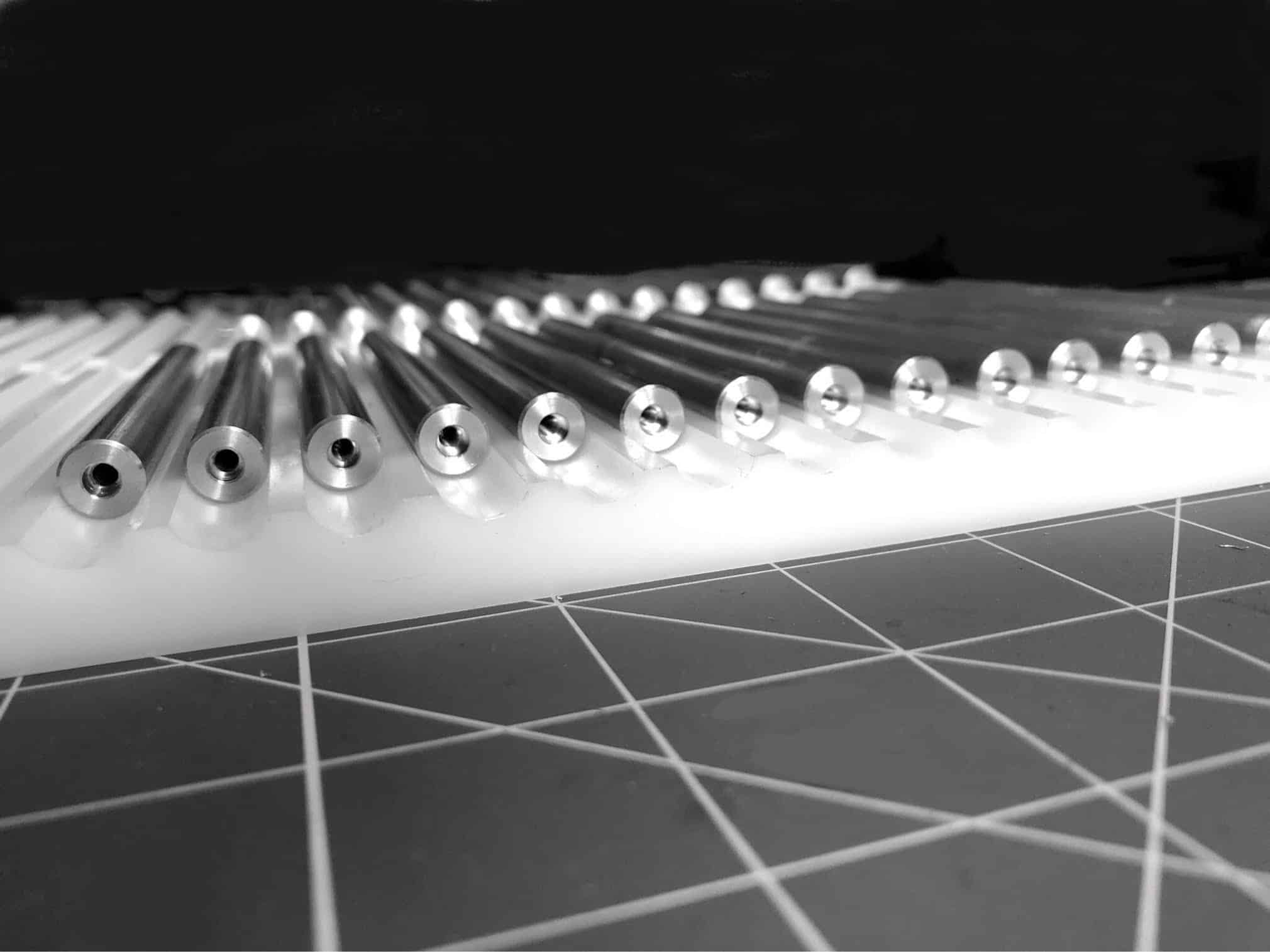

Well, he did what anyone with access to metal shaping machines and decades worth of design experience would do: he made one himself. And now he’s selling them to other enthusiasts. On a metal lathe, Isaac makes the spring bar tool by hand. The 6061-T6 aircraft-grade aluminum rod is tapered on the ends to make bracelet and strap swaps easy and comfortable. Mil-spec rubber O-rings are semi-recessed into the tool to allow for good grip. The tool—which is made from American-made materials—uses Burgeon 6767-xx replaceable tips.

On a metal lathe, Isaac makes the spring bar tool by hand. The 6061-T6 aircraft-grade aluminum rod is tapered on the ends to make bracelet and strap swaps easy and comfortable. Mil-spec rubber O-rings are semi-recessed into the tool to allow for good grip. The tool—which is made from American-made materials—uses Burgeon 6767-xx replaceable tips.

The development and manufacturing of the spring bar tool came out of necessity. It’s a theme that runs through much of the Chicago-native’s career.

Featured Videos

Featured Videos