When you hold a watch in your hand, or strap it to your wrist, it becomes immediately apparent when a great level of thought and care has gone into making it. With a watch made by Grand Seiko, from the moment the clasp snaps shut, or the movement comes to life, it’s quite obvious that an inordinately high level of craft has been applied. This is an immensely satisfying and increasingly rare feeling, and it imbues Grand Seiko watches with a sense of timelessness that is hard to find in any modern watch, regardless of price point. For Grand Seiko, an excellence in craftsmanship is clear in three key areas that make these watches highly distinct and truly special: the case, the dial, and the movement.

The Case

To understand Grand Seiko’s approach to case design, you first need to unpack the concept of “Grammar of Design.” Grammar of Design is the artistic principle that has guided the look, shape, and feel of Grand Seiko cases since the 1960s, when Taro Tanaka was charged with creating a new case in a new style that would be unique to the brand, setting it apart from the Swiss competition.

The cases that result from the application of these rules are like nothing else in watchmaking. Impossibly wide facets are mirror polished to perfection, creating light play and visual tricks of the eye that never get tiring. And while Grand Seiko has evolved these rules throughout the years as manufacturing technology and styles change and shift, they remain surprisingly durable and link today’s watches to the Grand Seiko’s of the past in interesting ways. The point is not to adhere to every rule 100% of the time, but to create watches within a framework that provides coherence across models and promotes a high standard of quality.

Those who are coming to the brand for the first time are often immediately impressed by the quality of Grand Seiko’s case finishing. There is simply no other brand providing this level of finishing to their cases at anything approaching Grand Seiko’s price point, and it makes the watches feel special, like you’ve tapped into a horological secret. The wow-factor is a direct result of the Zaratsu polishing process.

“Zaratsu” is simply the Japanese pronunciation of the name of the European company that built the polishing machines used by Grand Seiko for the application of the distinct mirror finish seen on so many of their watches. Grand Seiko craftspeople now use in-house versions of these machines and do so in a nontraditional way, however, by holding the surface of the case to be polished against the front of the wheel, rather than its side.

The rapidly spinning metal disc is coated with sandpaper and will eventually produce a surface with a lustrous, bright quality to it, but getting to that point takes a great deal of skill, and Grand Seiko craftspeople train for years to perfect the art of Zaratsu polishing. Grand Seiko polishers apply varying amounts of pressure for different amounts of time to achieve the desired result, and there’s no manual for this process – a craftsperson must innately understand how their actions move the case toward a perfect mirror shine.

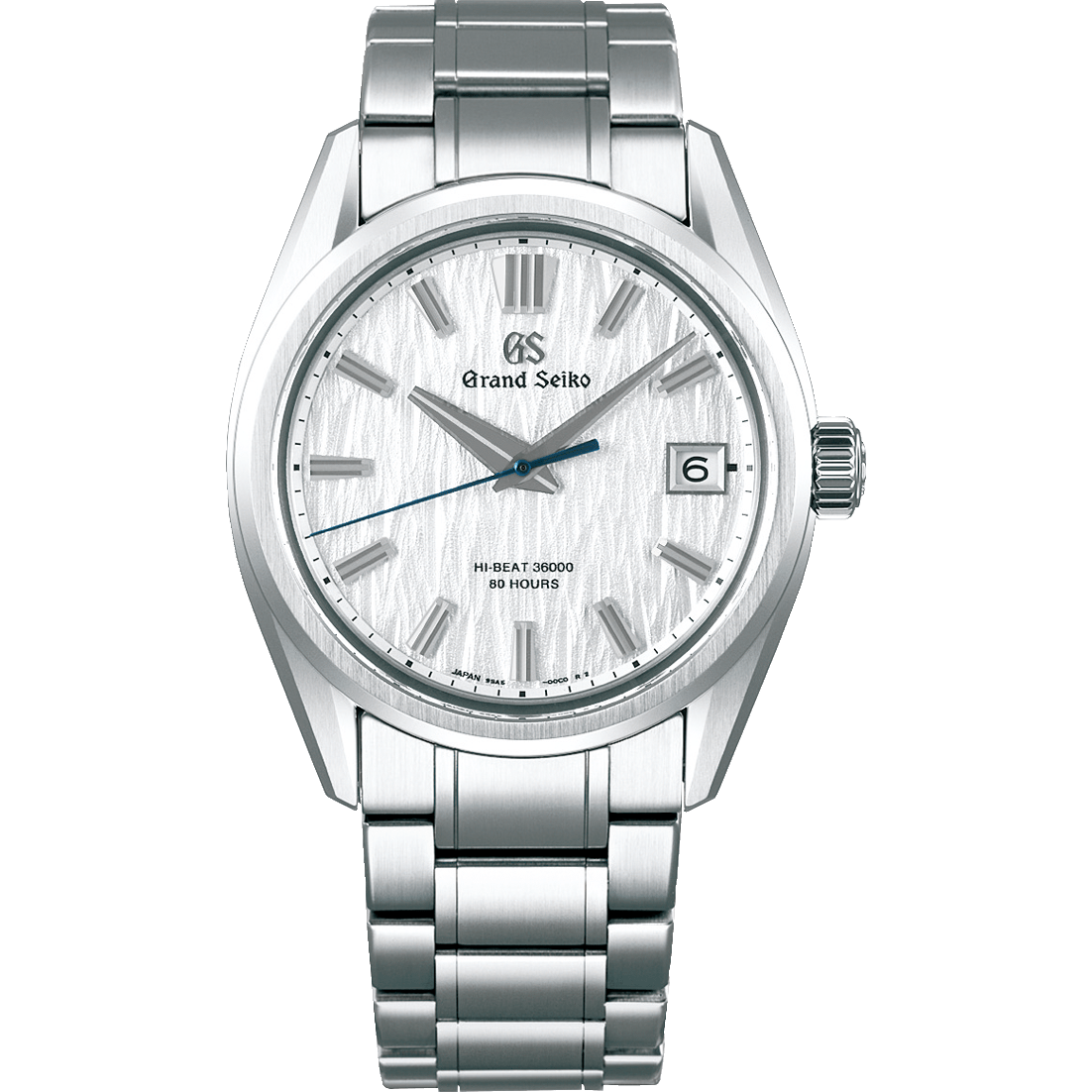

The dramatic angles associated with the Grammar of Design and impressive precision of a Zaratsu polish come together in a variety of interesting ways in Grand Seiko’s diverse catalog, but perhaps the most well-known and signature case style throughout Grand Seiko’s history is the 44GS case. This is the case shape that firmly established Grand Seiko’s style in 1967, and its unique profile is echoed throughout the collection today, in both subtle and explicit ways. These principles also look ahead, and as we can see with the newer 9 Series designs like the SLGH005 “White Birch” which debuted earlier this year, the rules set forth at the brand’s founding are flexible and adaptable and promise to create exciting contemporary designs for years to come.

The Movement

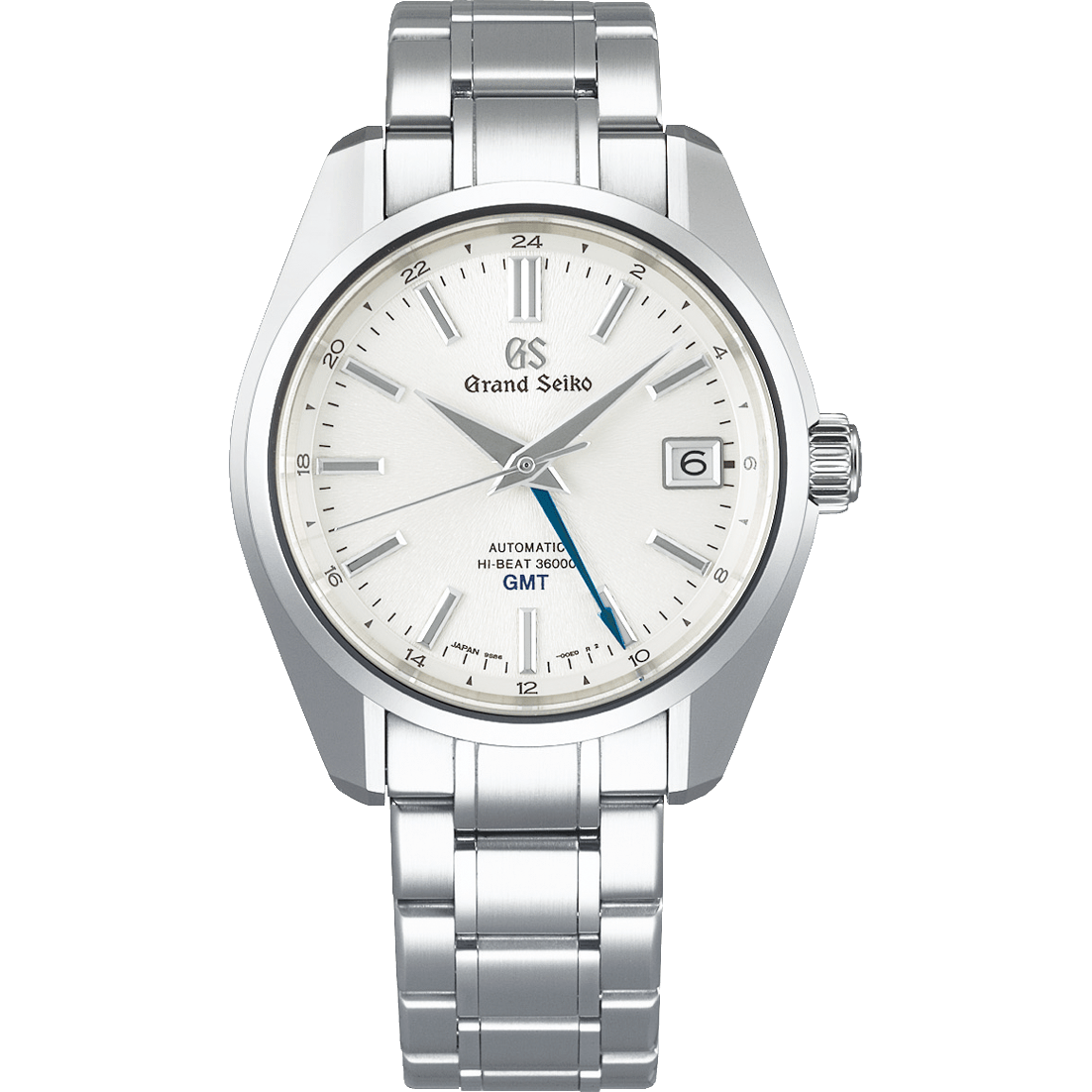

Grand Seiko movements, made in-house to exacting standards, are largely symbolic of the entire Grand Seiko watchmaking operation in the way their production combines high-end technology and manufacturing techniques with classic craftsmanship that’s rooted in centuries of tradition. Unlike most manufacturers, Grand Seiko has mastered the art of movement making in a variety of different ways. Their mechanical movements run the gamut from traditional, relatively simple calibers made in traditional ways to dramatically tech-forward creations that are made using the latest state-of-the-art technology.

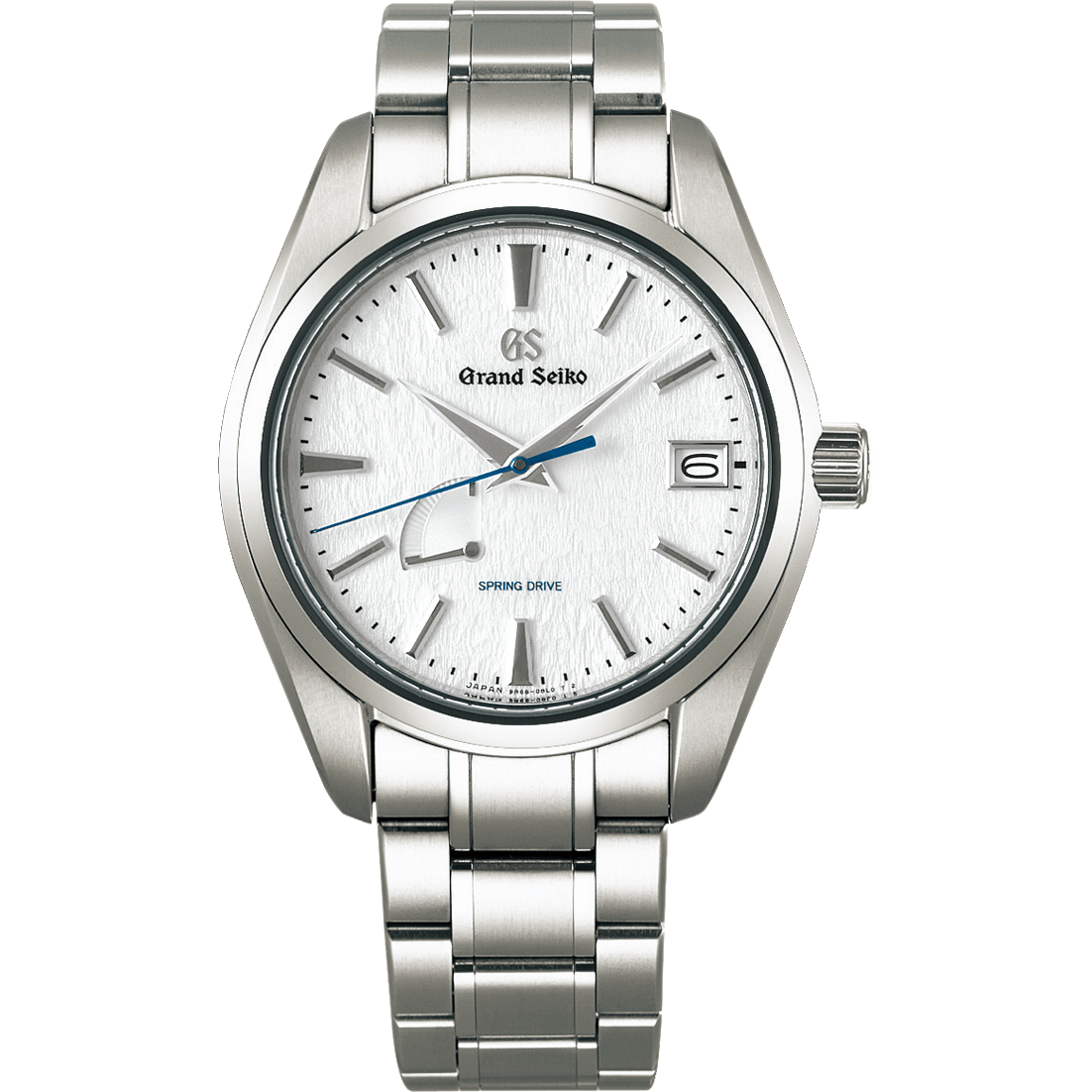

Grand Seiko’s mechanical movements represent the best in a historic style of watchmaking that goes back hundreds of years, and yet it’s always clear that the brand is looking ahead, creating new standards for precision and accuracy along the way. Spring Drive, for example, is Grand Seiko’s own invention, a combination of the best of quartz and mechanical timekeeping, without the deficiencies of either. It’s their boldest statement and a technological marvel.

The 9S family of mechanical movements is, on the one hand, the simplest and easiest to understand series of movements that Grand Seiko makes. While any mechanical watch movement is inherently complex, on the surface, the 9S calibers would seem to be more humble affairs than the souped-up quartz watches or magnificent Spring Drive movements made by the brand. But the 9S movement remains an important achievement, pushing precision to its limits, and a deeper look reveals that even in the realm of traditional watchmaking, Grand Seiko is innovating like no other brand.

Consider Grand Seiko’s Micro Electro Mechanical Systems (MEMS) technology that’s employed in the making of their mechanical movements. MEMS processes allow for Grand Seiko engineers and watchmakers to craft components with the tightest of tolerances. Precision in crafting the hundreds of components that make up a mechanical watch movement leads to precision in timekeeping, which is always the ultimate goal for Grand Seiko.

This technology has led to innovations like the 9SA5 caliber, Grand Seiko’s next-generation high-frequency movement, which features a dual impulse escapement that allows for an impressively stable rate over an extended (80 hour) power reserve. This kind of innovation, only possible with MEMS technology, is matched with the craft of Grand Seiko watchmakers, each an artisan in their own right, capable of finely adjusting hairsprings by hand, and applying just the right amount of heat to a hand to achieve the perfect shade of blue, over and over again.

This attention to detail and precision engineering leads to timekeeping accuracy that is second to none. Across the entire lineup, Grand Seiko calibers perform at levels that exceed chronometer standards. The New GS Standard, established by the brand in 1998, set more stringent standards than any developed previously, with some mechanical movements regulated to +4/-2 seconds per day.

Movements in the 9S family of mechanical calibers are tested over a 17-day period, and each movement must meet various standards across six different timing positions and three temperatures. Daily variations must not be outside Grand Seiko’s strict tolerance rates in order to meet the standards set forth by the brand. And for Grand Seiko’s 9F quartz movements, precision is taken to even greater extremes, with accuracy expected within +/- 10 seconds per year.

Spring Drive movements are a category unto themselves and feature a second hand that moves across the dial in an impossibly smooth glide. Spring Drive technology combines the gear train and unlimited renewable power of a traditional mechanical watch through the use of a mainspring with the accuracy of quartz. A Spring Drive powered watch is capable of stunning accuracy, with rates veering no more than one second per day. Looking broadly at Grand Seiko, it’s no wonder that they were able to create this fusion of quartz and mechanical, as they’re one of the only brands to master both types of movements.

Movement finishing is prioritized across all Grand Seiko calibers, regardless of movement type. Well-defined striping is present on the plates of both relatively simple mechanical movements, like the hand-wound 9S63, and far more complex creations, like the 9R86 chronograph movement. The 9R86, an automatic chrono with a column wheel, features a skeletonized rotor that keeps the gear train on display to curious observers. Spring Drive movements, too, are inherently fascinating to watch, as the constantly engaged glide wheel that is key to the smooth sweep of the second hand creates a show like nothing else in horology. Calibers like the 9R65, a Spring Drive movement with 72 hours of power reserve rated to accuracy within 15 seconds per month, have a clean and minimalist aesthetic, which pairs nicely with the high technology behind the movement itself. Every Grand Seiko movement, just like any other component that goes into these watches, is a clear expression of both technical mastery and artistic craft.

The new 9SA5 caliber, Grand Seiko’s latest and most advanced high-frequency movement, is a monumental achievement. It solves a number of horological problems, improves on Grand Seiko’s already best-in-class hi-beat technology, and has an aesthetic appeal that matches the beauty of the watches it powers.

The technological advancements are evident on several fronts. First, and perhaps most significant, the 9SA5 makes use of a brand-new escapement, which is an exceedingly rare event in contemporary watchmaking. The dual impulse escapement seen here impacts the balance twice while using no additional energy compared to a traditional escapement, allowing for a dramatic increase in efficiency, and an 80-hour power reserve (thanks to an additional barrel) that maintains an exceptional degree of precision during the entire running time. Grand Seiko has also completely rethought the layout of the gear train in the 9SA5, with the mainspring barrel and gear train now arranged horizontally. This allows the movement to be significantly thinner (about 15%) than the brand’s previous hi-beat caliber and opens up new doors to watch designs that were closed previously.

And the caliber itself is stunning to look at. The rotor is skeletonized, allowing for a view of the movement with fewer obstructions while the watch is running. Elaborate striping has been applied to the bridges of the 9SA5, dramatically framing the free-sprung balance, the movement’s literal and figurative heartbeat. Most impressively, visible bevels are present along the ridges of the movement plates, a sign to connoisseurs of movement finishing that Grand Seiko has improved on what was already a high standard of quality.

Impressive as they are, Grand Seiko’s case and movement finishing only tell part of the story. In the second part of this series, coming soon, we’ll be taking close look at the brand’s dials, which frequently tell a story in a way that only Grand Seiko can.

Featured Videos

Featured Videos