Bremont and ejection seat manufacturer Martin-Baker have been working with another for over a decade now, and they’re partnership has laid the groundwork for innovation in both the testing and watchmaking process. These two British companies are most certainly birds of a feather, producing their own specialty products with a stamp of dependability that signifies the extensive testing and meticulous quality control that goes into each and every component. They both are constantly pushing the boundaries of what’s possible in their respective industries. It’s no surprise that when Bremont brought watchmaking back to U.K. shores with its series of Caliber ENG300 movements, they tapped into Martin-Baker’s intense equipment and performance testing program. That idea has evolved to what is now the foundation of Bremont’s MB range and created a whole new category of testing, as well as set a brand new standard for the pilots watch.

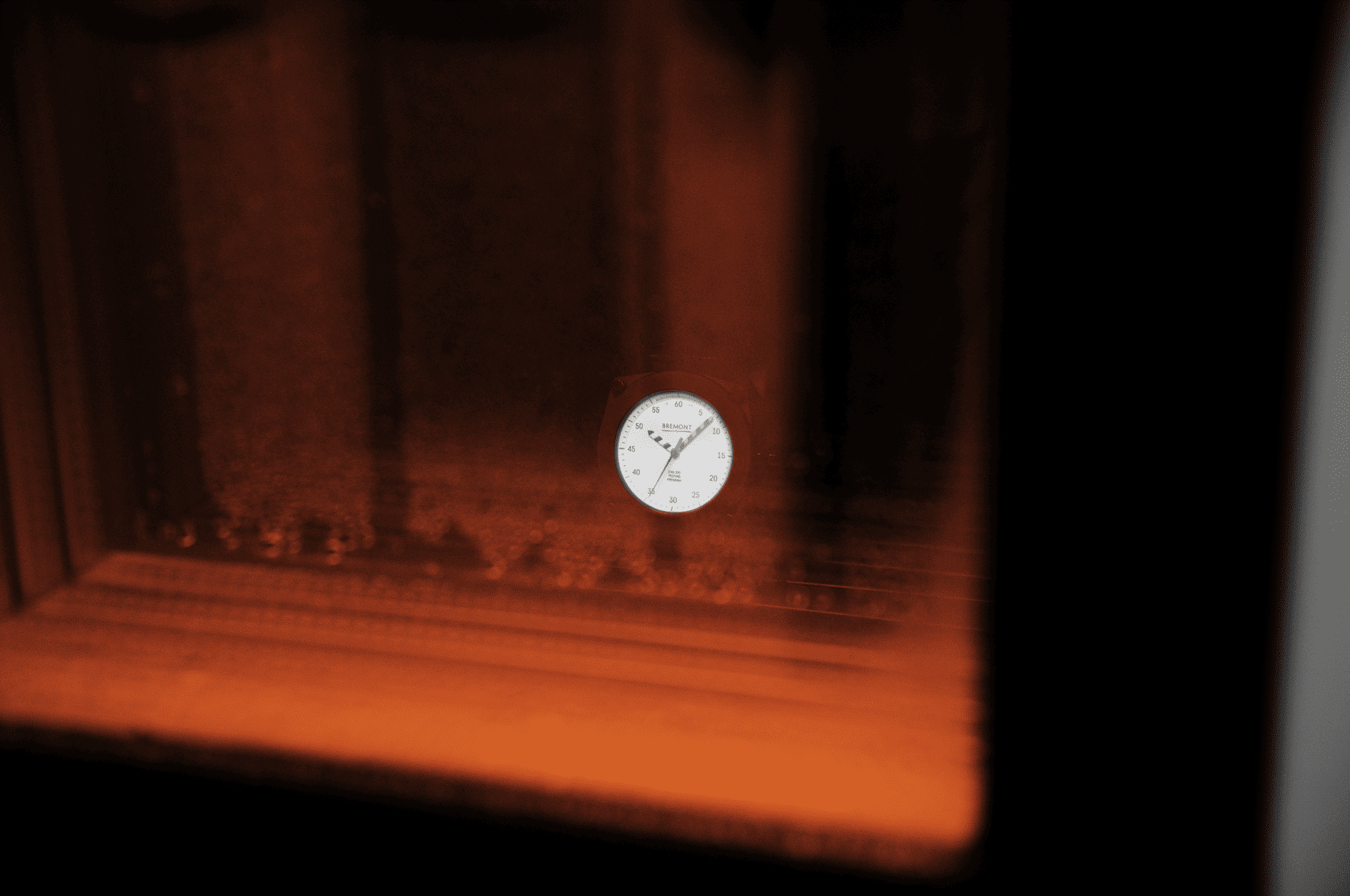

Bremont and Martin-Baker’s latest collaborative project looks forward by looking back – not at their rich history in engineering and technical ingenuity, but at the MB testing program itself and the actual test instrument used by Bremont. In order to test the viability of their Caliber ENG300 movement series, Bremont created a special housing that was attached to the dashboard of an ejection simulator. Bremont then went a step further by affixing a set of carbon fiber lugs to that special housing and strapped it to the wrist of a test mannequin to more accurately test the actual scenarios and stress forces enacted on to the now, ‘test watch’. During this Live Ejection Test alone, that instrument is subjected to upwards of 30 G’s, shock from multiple contact points and extreme temperatures from seat ignition. Needless to say, the instrument passed every test with flying colors, and is now the main inspiration of Bremont’s latest addition to the MB range; callsign, Viper.

Featured Videos

Featured Videos