In Part 1 of our “What Makes It Tick” series, we touched on the mainspring, which stores the power that drives the movement. The release of that power, however, needs to be controlled in some way. This is where the escapement and balance assembly come into play.

There are a number of different styles of escapement, but for the sake of simplicity we’ll focus on the most common style we see today: the Swiss lever escapement. Over the course of this article we will examine each component of the escapement in detail.

The Escape Wheel – Explained

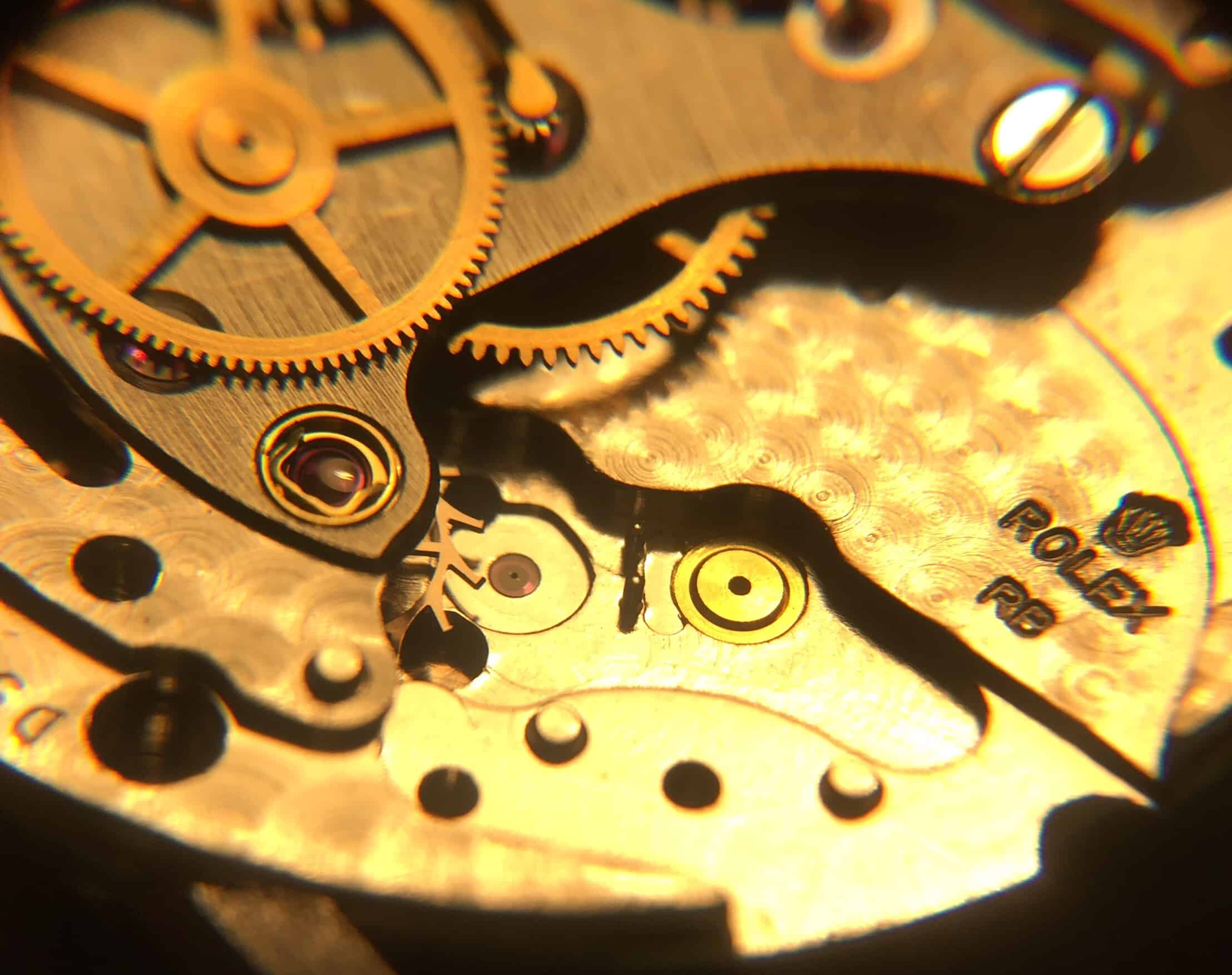

The escape wheel plays a very similar role to one of the gear train wheels, but it’s technically part of the escapement. It is the link, as it were, which connects the escapement and gear train of the movement. The escape wheel rotates like a train wheel, and its purpose is to transfer the energy from the mainspring to the balance. However, it only interacts with one wheel, unlike train wheels, which generally interact with two, or with one and the barrel. Instead of interacting with another wheel, the escape wheel interacts with the pallet fork, which is what simultaneously blocks and releases the power from the mainspring.

The Mechanics

The escape wheel has specially shaped teeth that are designed to interact with the pallet fork, which is how that power from the mainspring is able to be transferred to the balance. The escape wheel will have a varying number of teeth depending on the vibrations per hour (vph) of the movement, but more on that later. Escape wheels are commonly manufactured from steel, unlike train wheels, which are made from brass.

Featured Videos

Featured Videos