Though it’s typically easy enough for a collector to differentiate between various categories of watches, sussing out the technical definition of each of these categories is admittedly a more involved process. What precisely constitutes a dive watch, or a pilot’s watch? Is there a particular water resistance that must be met if a watch is meant to be used underwater, or a specific altitude or barometric pressure at which a pilot’s watch must be able to operate?

The International Organization for Standardization provides some help in answering these questions. ISO (which is not an acronym, but derived from the Greek isos, meaning “equal”) is an international body comprised of representatives from various national standards organizations whose purpose is to set international standards and guidelines for products and services. There are 162 member countries and funding is provided through a combination of organizations that manage specific products, subscriptions from member bodies, and the sale of standards.

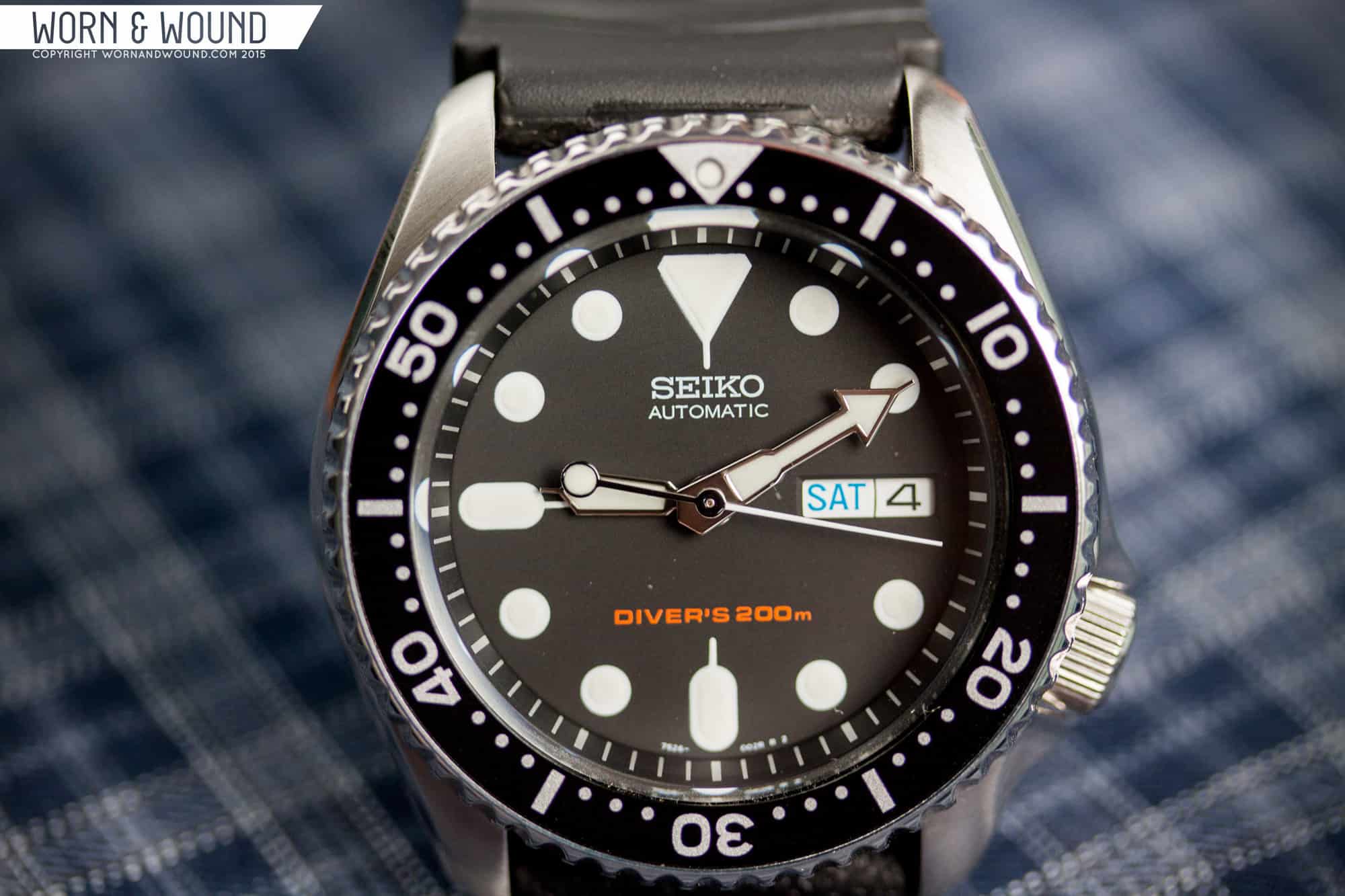

Chances are that if you actually SCUBA dive with your dive watch, you’ve at the very least heard of certain ISO standards in passing, the most well-known of which is likely the ISO 6425 (the German DIN 8306 is an equivalent). The 6425 standard provides water resistance specifications down to 100 meters, as well as minimum requirements for mechanical diver’s watches, such as:

Featured Videos

Featured Videos