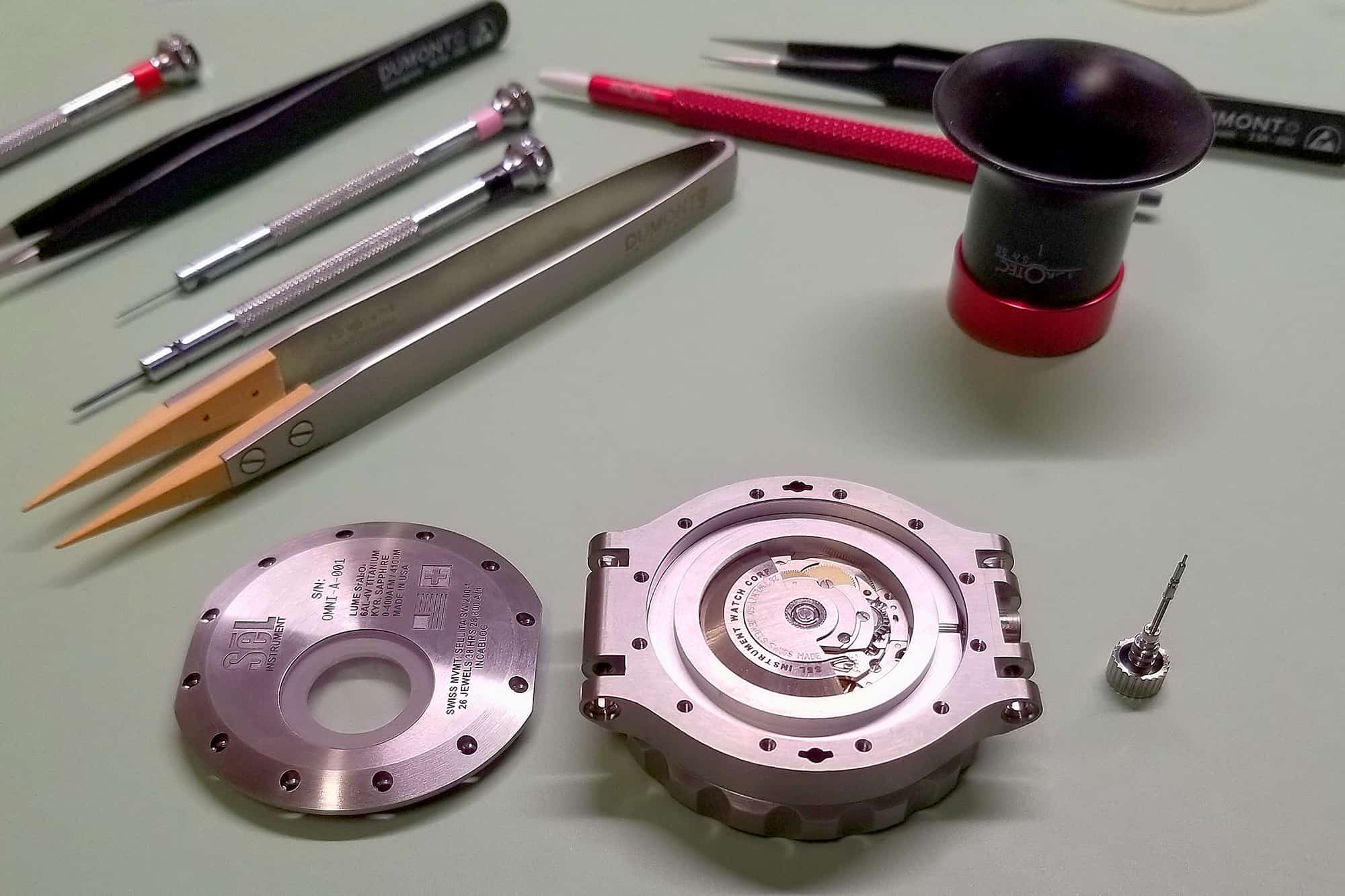

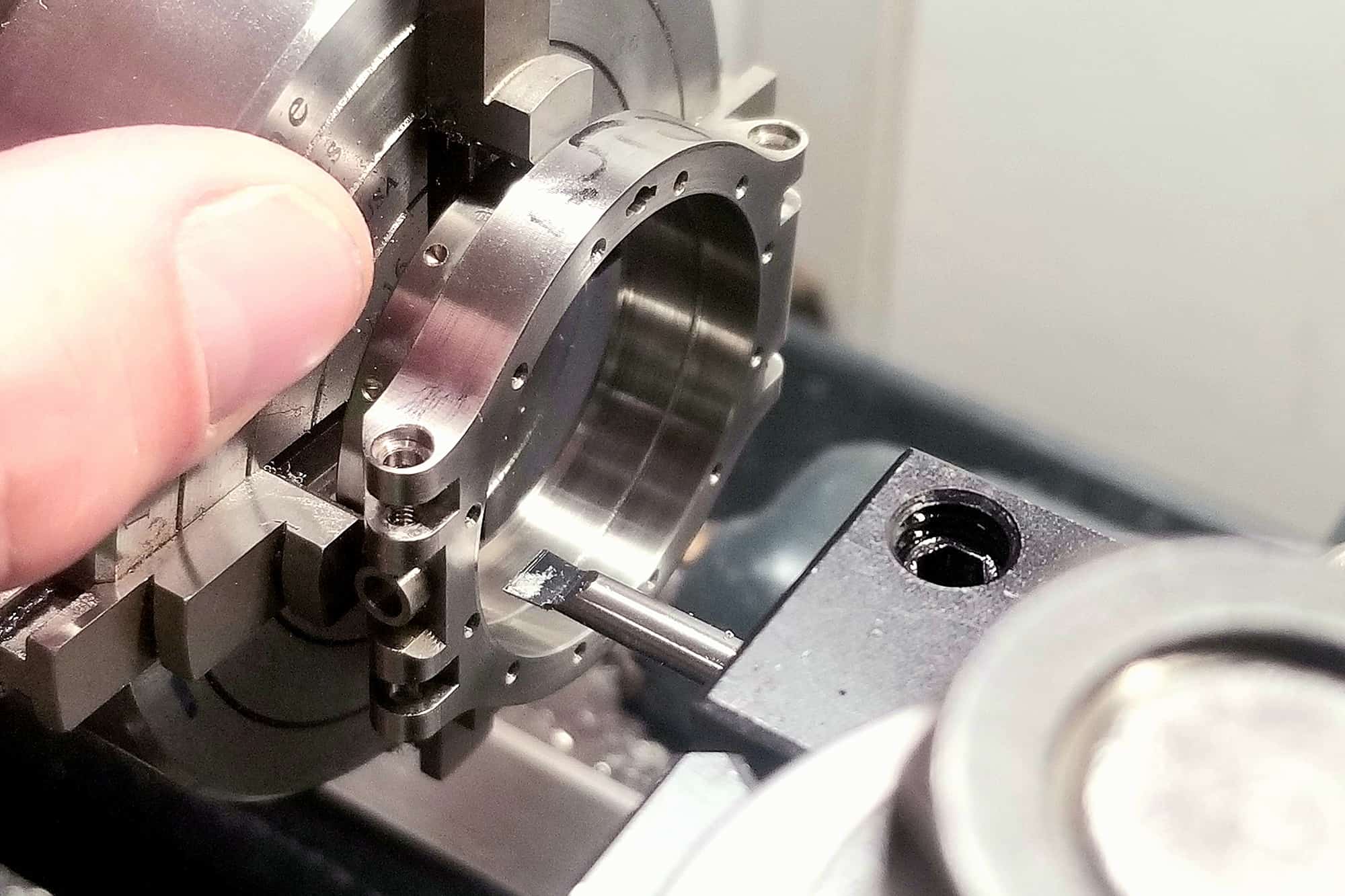

Between the innovative Wavlock clasp, the massive 6mm thick kyropoulos sapphire crystal, and the dive bezel that rides on silicon nitride balls for the smoothest possible movement without any discernible counter-rotation, the amount of research, technology, and pure problem solving that goes into each OmniDiver is truly impressive. So where does SēL go from here? Further expanding in-house production is priority number one, as it will allow the company to develop new products more quickly, and an increased flexibility in responding to customer needs. Also, robots.

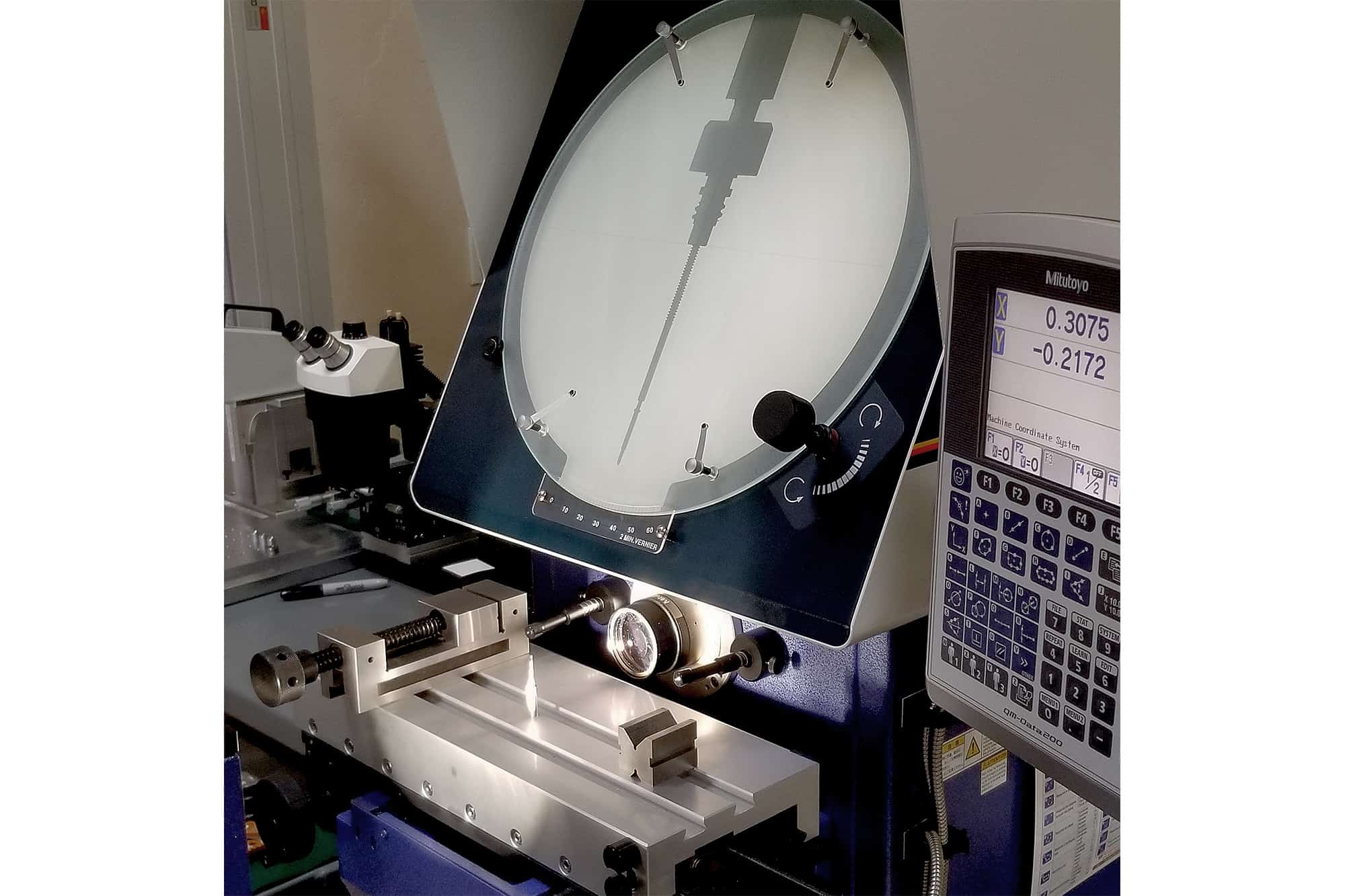

“We’re looking at adding robots to our CNC production line which would allow us to fully automate 3 shifts per day and bring costs down dramatically,” says McLean. “This type of investment can both increase margin for us, and reduce retail cost for the consumer.”

![]()

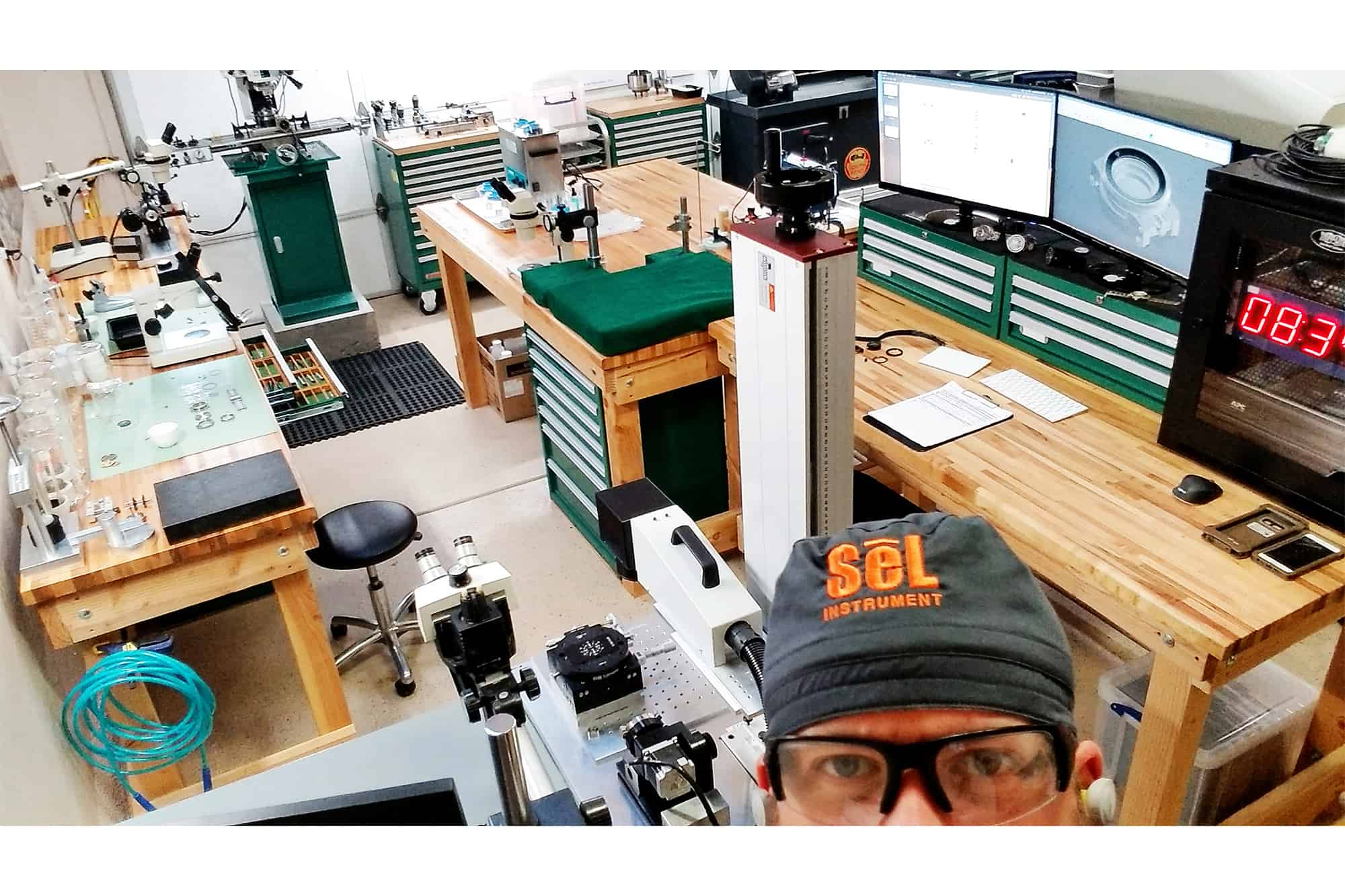

This really underlines SēL’s unique approach. While other watch brands, perhaps with a debt to history, focus on old-world handcraft and traditional watchmaking techniques as a way to lure customers to a world of luxury products, SēL embraces innovation at every turn, and celebrates doing things differently. “We never look for the easy way to do things – we look for the right way to do it,” says McLean.

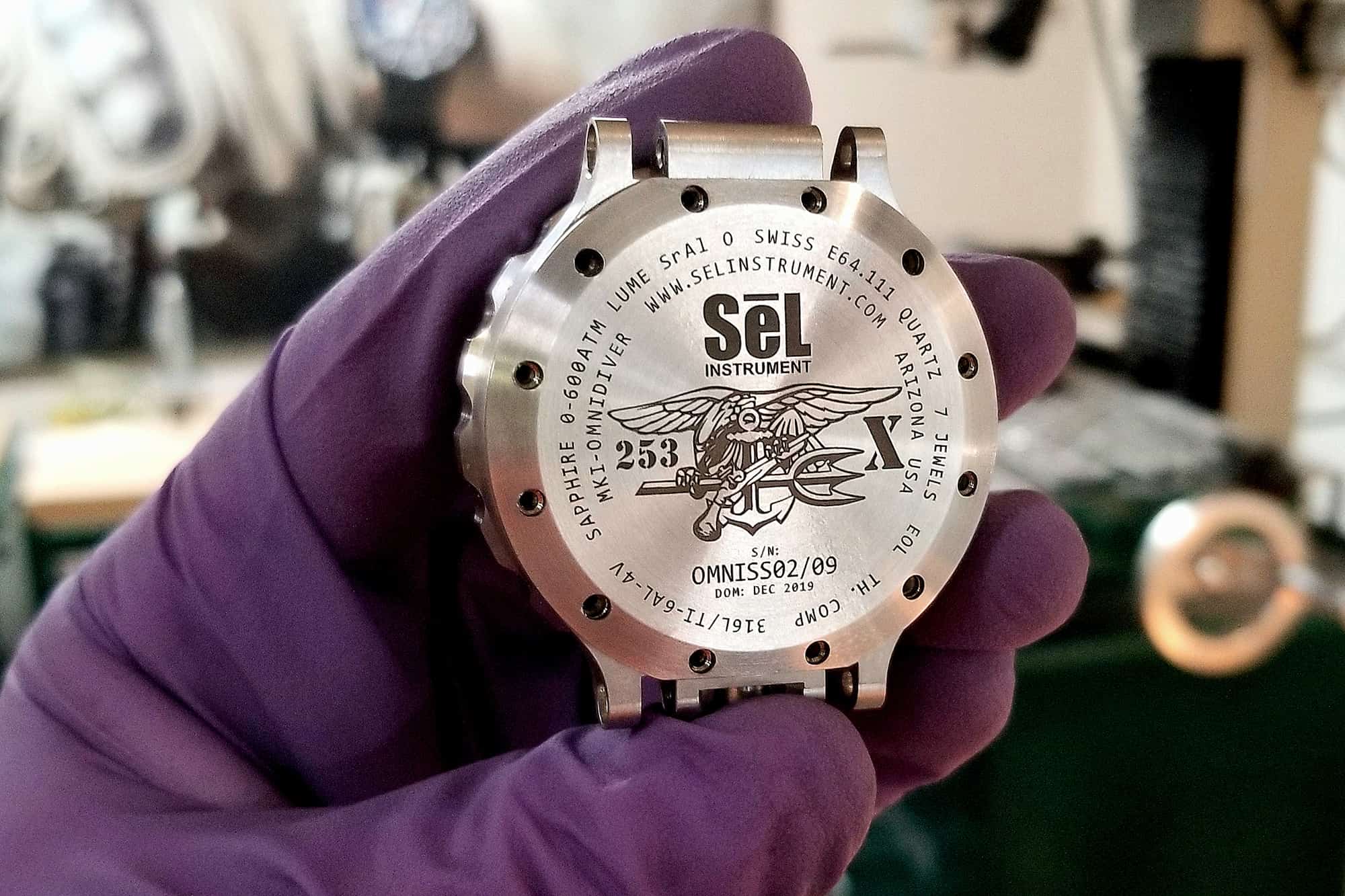

With a catalog that includes not just the OmniDiver, but the recently introduced and slightly less intense OPTx watch, a blacked out diver that’s a little smaller than the OmniDiver but still rated to 2,000 meters, as well as a series of straps and multi-tools in their Bombproof line, Sēl Instruments seems to be carving out a niche as a brand that’s capable of fabricating just about anything you can imagine, as long as it’s incredibly tough.

![]()

“We don’t fault anyone for thinking SēL watches are ‘over-built,’” says McLean, “for many, they totally are. But for people who live and work in the harshest environments on earth, our level of engineering and quality can make a huge difference.”

Featured Videos

Featured Videos