Tourbillons don’t often grace the pages of worn&wound as they are typically found in watches that cost tens to hundreds of thousands of dollars. It’s not a matter of not wanting to discuss them; it’s a matter of not having the chance. Yes, there are some “affordable” ones on the market, but they are one of those things that is tied so closely with the skill, craft and expertise of seasoned watchmaking, that inexpensive alternatives just don’t really make sense. Well, the other day I got to experience a tourbillon like no other, one that I am very excited to present to you.

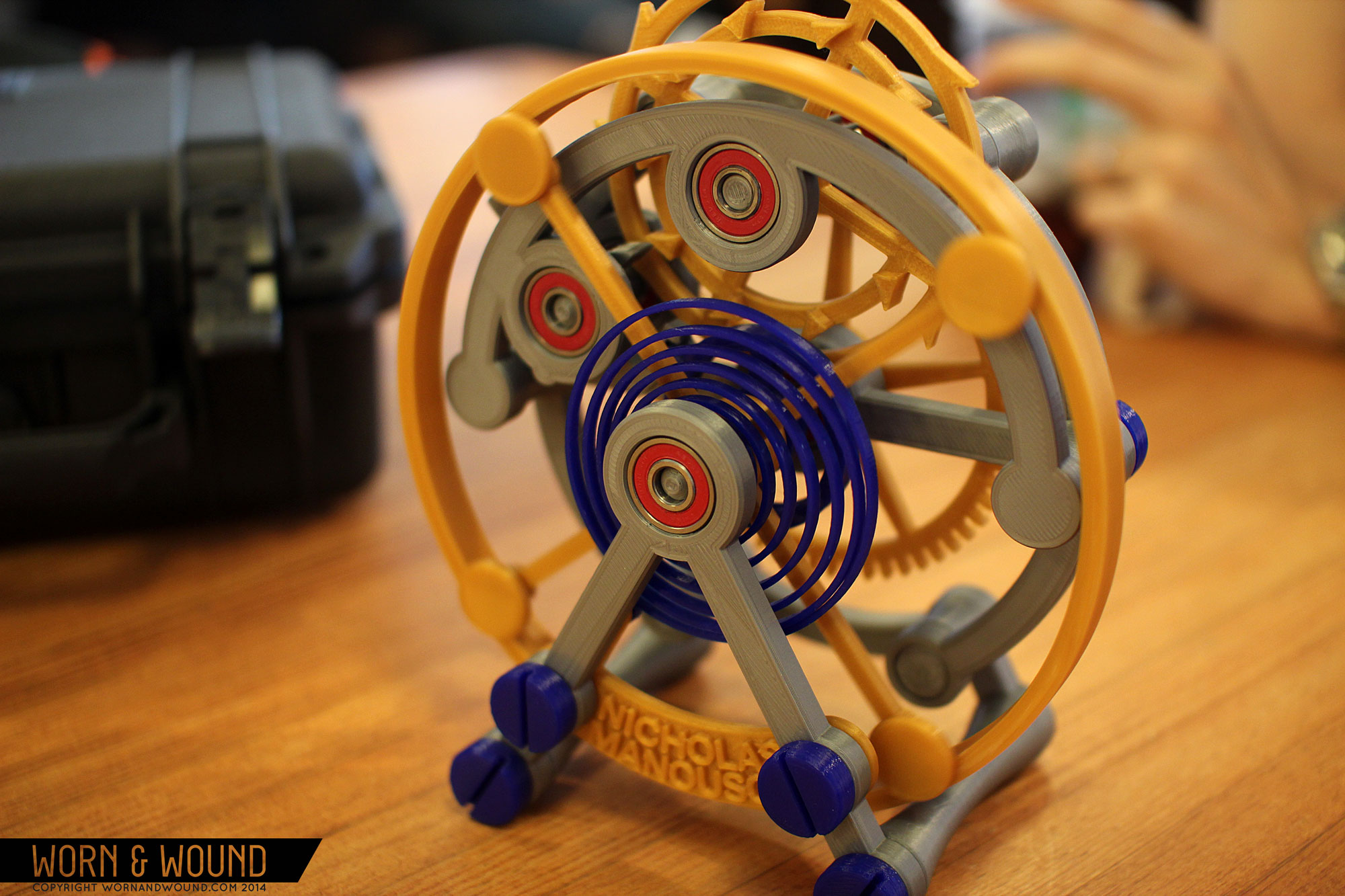

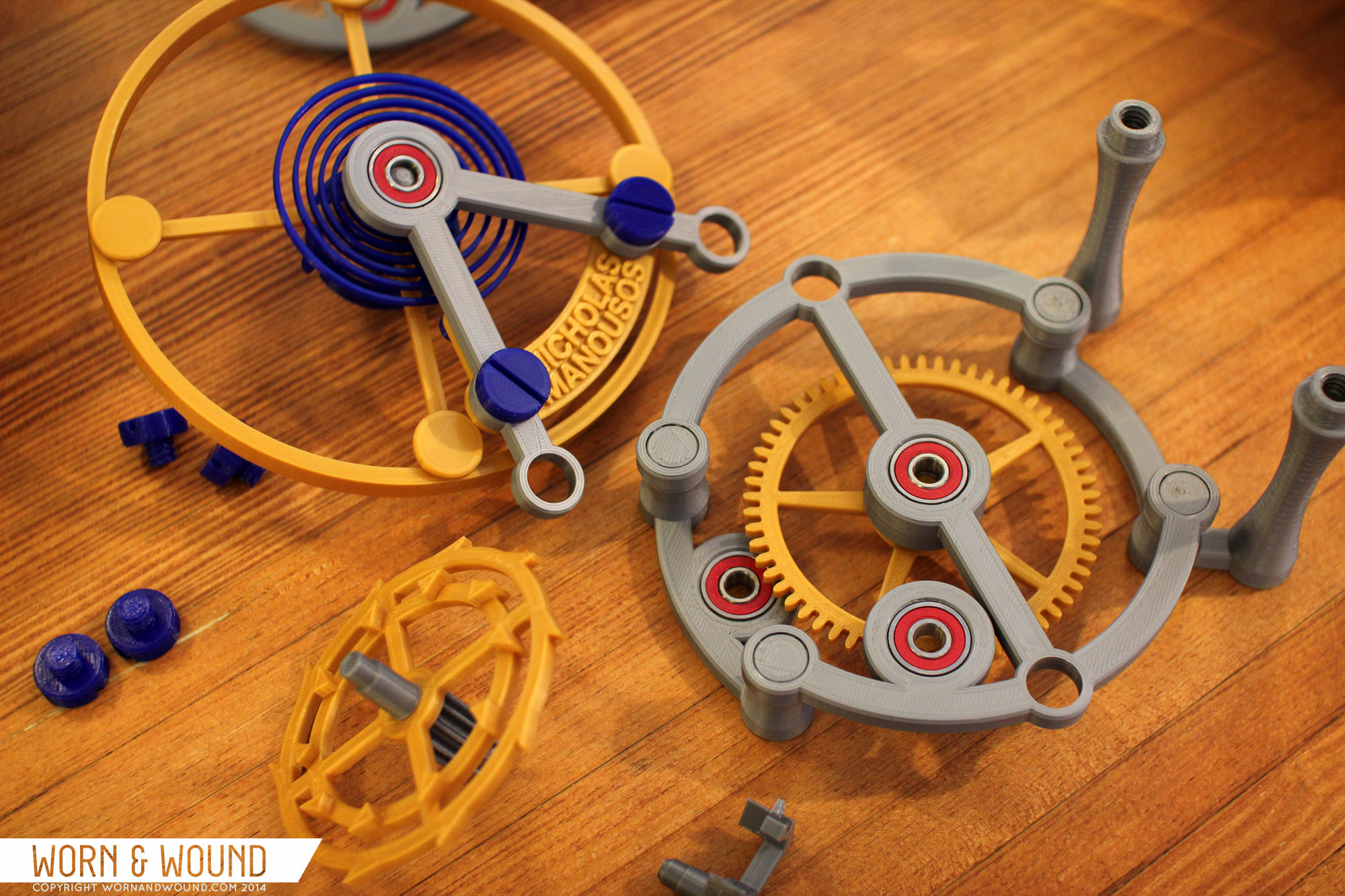

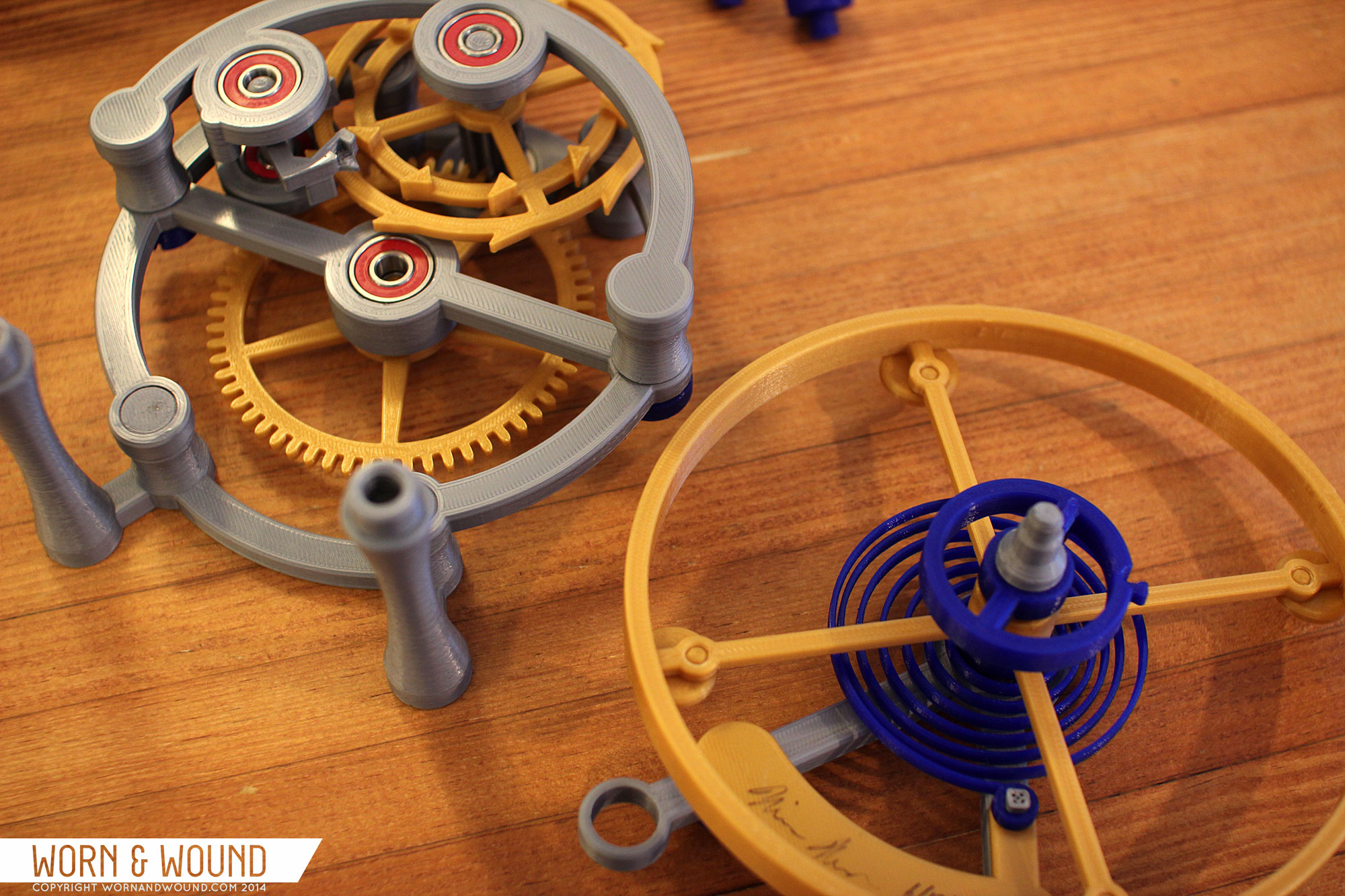

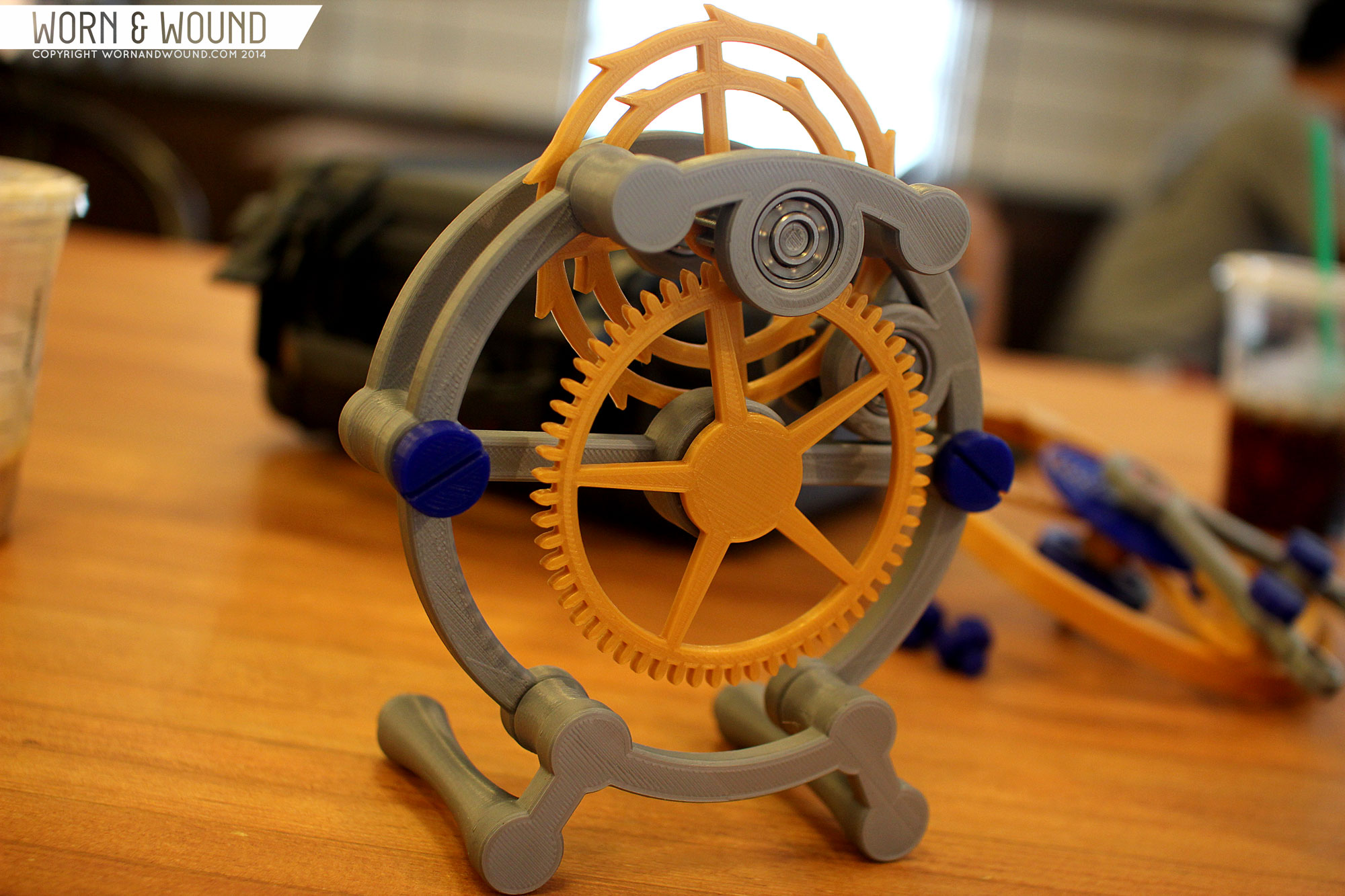

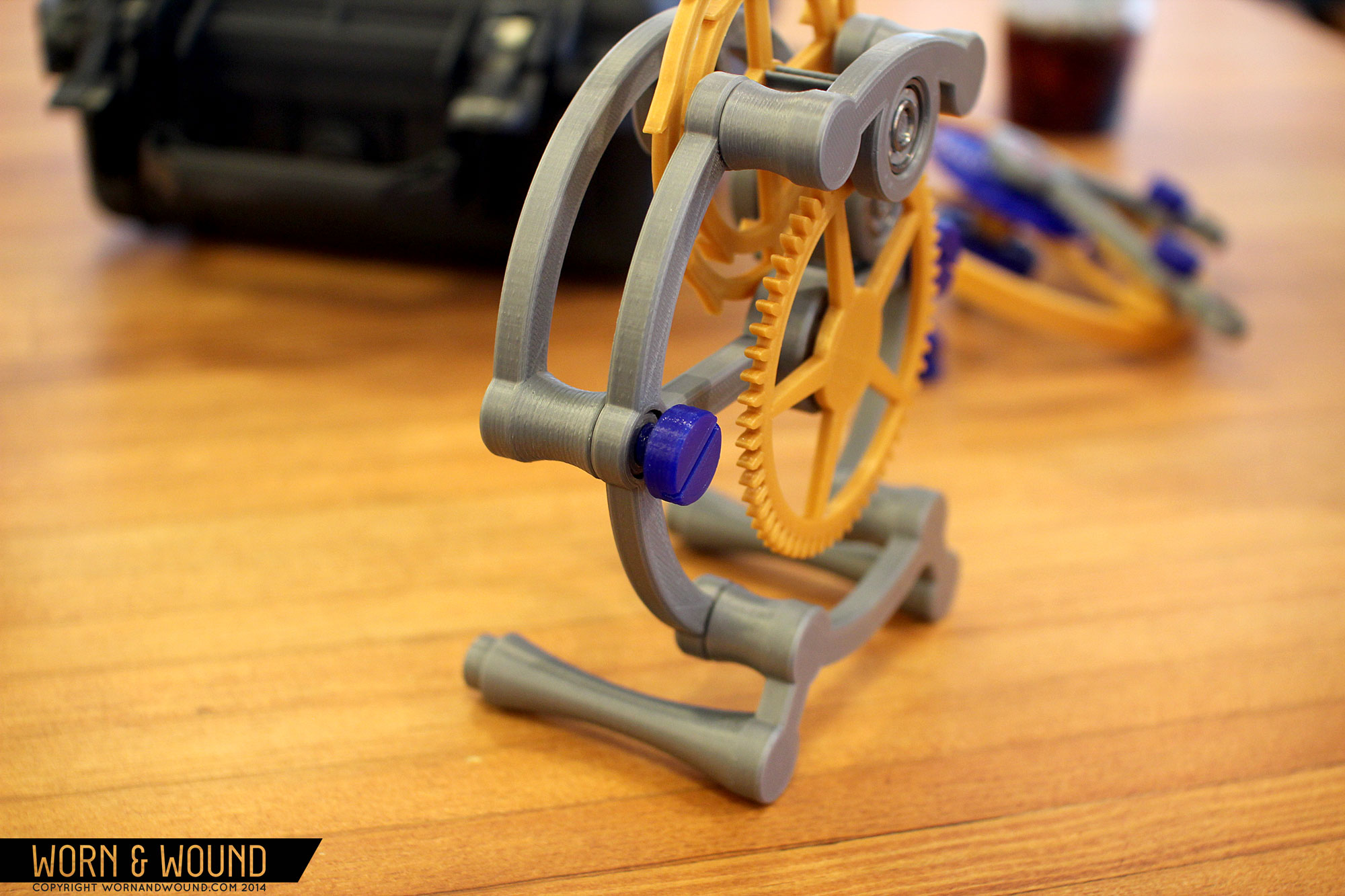

The Tourbillon 1000% doesn’t exist in a watch movement, rather it’s a 3D printed scale model of the complication. Designed, engineered and made by Nicholas Manousos, it’s the result of three years of engineering and design, and it stands several inches tall with large parts all clearly demonstrating the actions of the escapement and tourbillon carriage. It’s fun and colorful, like a child’s toy, but it shows a very complicated piece of horology in action.

The Tourbillon 1000% doesn’t exist in a watch movement, rather it’s a 3D printed scale model of the complication. Designed, engineered and made by Nicholas Manousos, it’s the result of three years of engineering and design, and it stands several inches tall with large parts all clearly demonstrating the actions of the escapement and tourbillon carriage. It’s fun and colorful, like a child’s toy, but it shows a very complicated piece of horology in action.

Featured Videos

Featured Videos