3D printing has come a long way since its early days. As the technology improves and expands to new applications, it continues to attract artists, inventors, and hobbyists alike. Among them, watch lovers, too. Today, we’re pulling two articles from our archives that cover one area where horology and 3D printing merge to create something really cool–a tourbillon.

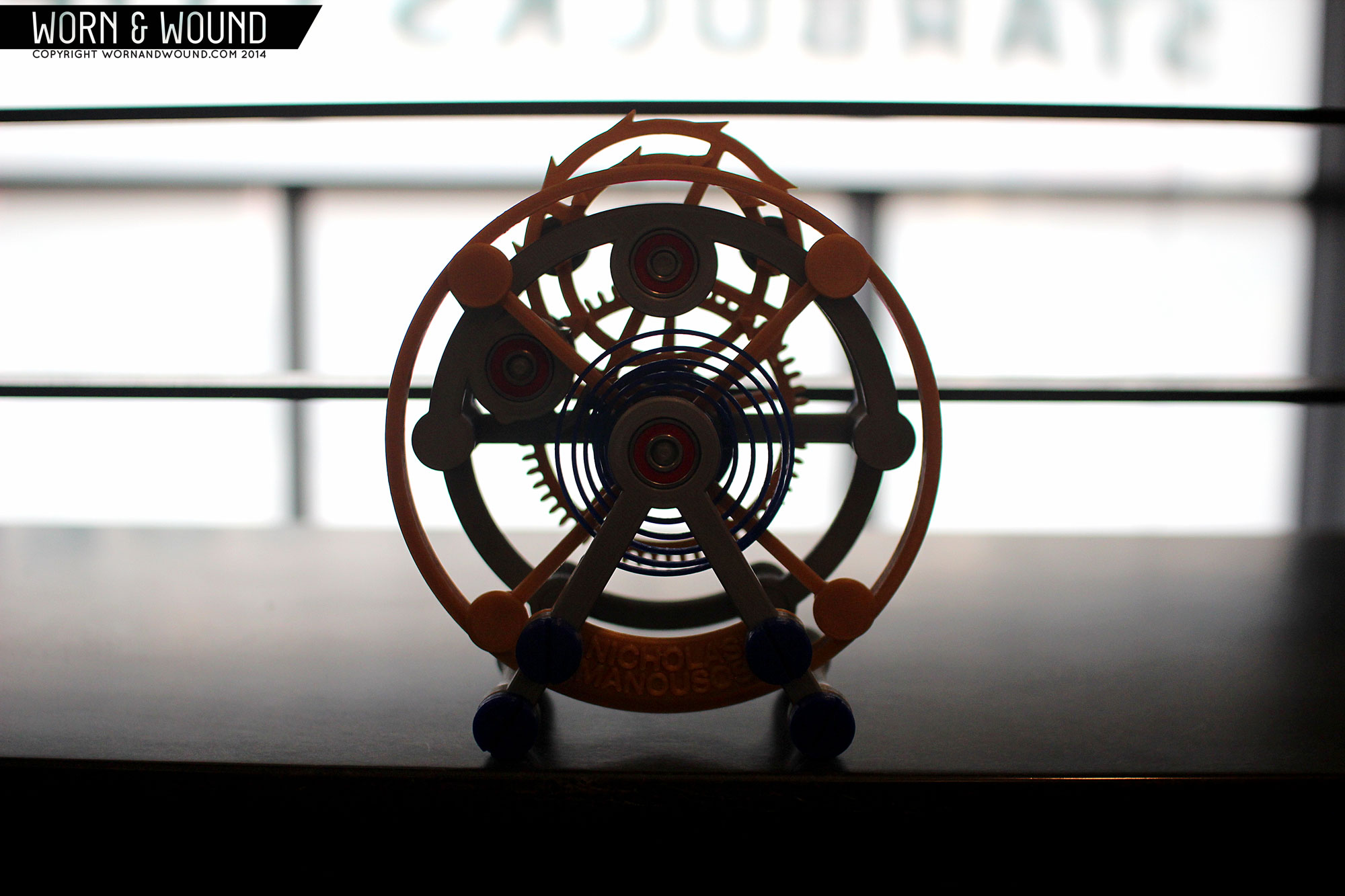

Tourbillon 1000% by Nicholas Manousos

In 2014, Nicholas Manousos—a name that may sound familiar if you’re a regular Hodinkee reader (he’s their Technical Editor) or if you’re a member of the New York Horological Society (he’s the President)—was just a few years out of watchmaking school (the Nicolas G. Hayek Watchmaking School, to be exact). At the time, Nicholas had a very cool project under his belt. Working out of his apartment, Nicholas had designed and 3D printed a functional scale model of a tourbillon—something he dubbed the Tourbillon 1000%. We met with Nicholas to check out his contraption, and needless to say it was very cool.

In 2014, Nicholas Manousos—a name that may sound familiar if you’re a regular Hodinkee reader (he’s their Technical Editor) or if you’re a member of the New York Horological Society (he’s the President)—was just a few years out of watchmaking school (the Nicolas G. Hayek Watchmaking School, to be exact). At the time, Nicholas had a very cool project under his belt. Working out of his apartment, Nicholas had designed and 3D printed a functional scale model of a tourbillon—something he dubbed the Tourbillon 1000%. We met with Nicholas to check out his contraption, and needless to say it was very cool.

For the full article, click here.

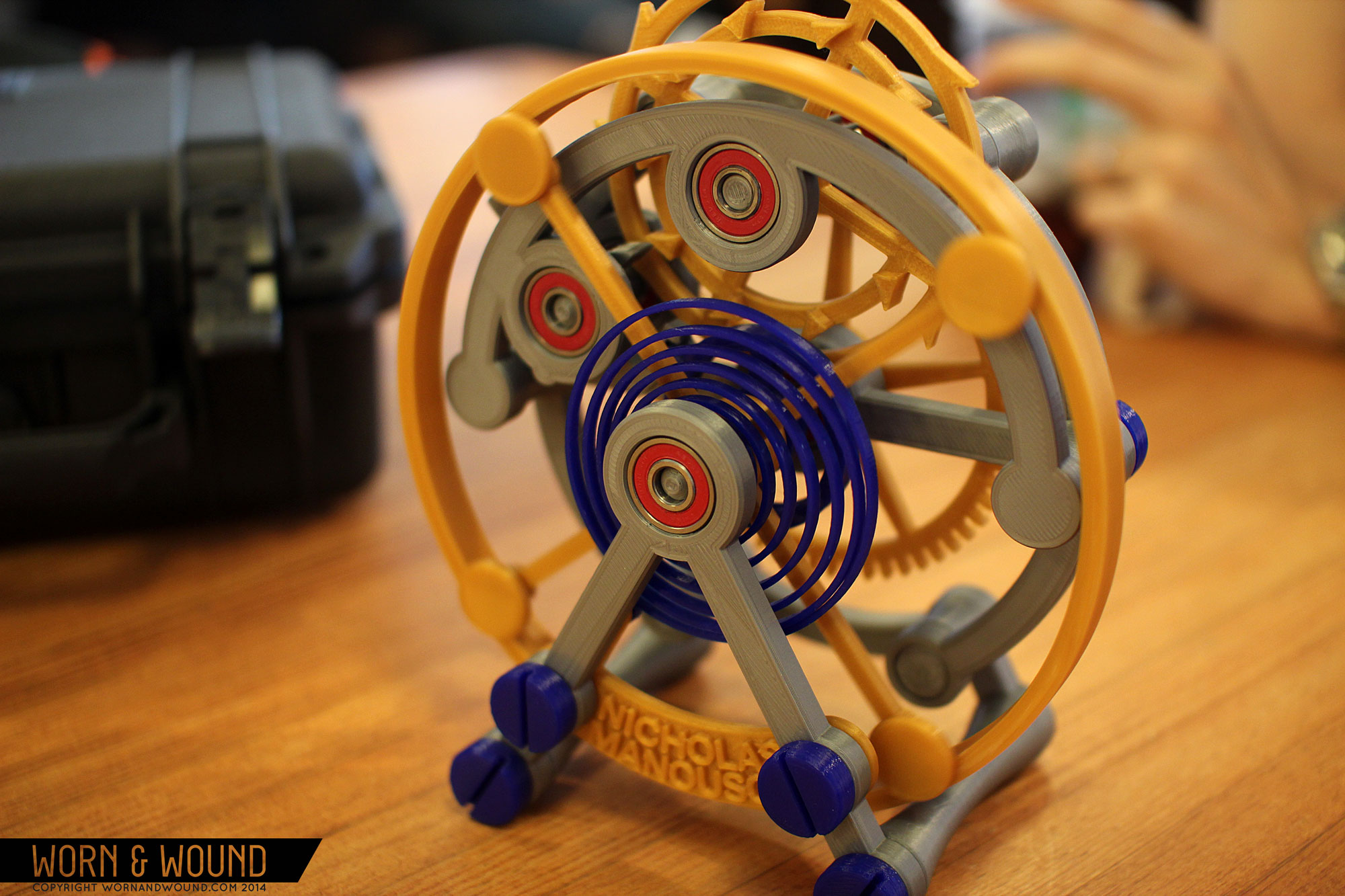

The Clockwerk 3D-Printed Triple-Axis Tourbillon by Adam Wrigley

Then last year, we met Adam Wrigley. A mechanical engineer at Frog Design, Adam stopped by our offices to show off something really cool—a 3D printed triple-axis tourbillon he called Clockwerk. Adam, who has long been fascinated by watches (and who during our meeting wore an Omega “First Omega in Space” Speedmaster) was deeply inspired by the Vianney Halter Deep Space Tourbillon. So much so, in fact, that he reverse-engineered the $200,000 watch with a little research and by watching YouTube videos of the Deep Space in action (remember, this is a guy with no formal watchmaking training). We talked to Adam, snapped some photos, and cut together a video of our interview and the Clockwerk in action.

Then last year, we met Adam Wrigley. A mechanical engineer at Frog Design, Adam stopped by our offices to show off something really cool—a 3D printed triple-axis tourbillon he called Clockwerk. Adam, who has long been fascinated by watches (and who during our meeting wore an Omega “First Omega in Space” Speedmaster) was deeply inspired by the Vianney Halter Deep Space Tourbillon. So much so, in fact, that he reverse-engineered the $200,000 watch with a little research and by watching YouTube videos of the Deep Space in action (remember, this is a guy with no formal watchmaking training). We talked to Adam, snapped some photos, and cut together a video of our interview and the Clockwerk in action.

For the full article and video, click here.

Featured Videos

Featured Videos